Very neat. Looks like it would feed very fast, did you have any problem getting it adjusted to feed the amount you wanted?

Any problems with the lid at the end getting hung up? I was thinking that you could put a weight on it to help hold it closed, or even a magnet with an opposite pole magnet on the auger, offset from center. When the auger turns, it would release the door for 3/4 of the rotation, then snap it back closed and hold it when the magnet came around again. Setup you controller to only rotate 360 degree turns, and you'd be set.

My feeders have always gummed up eventually, due to moisture in the air.

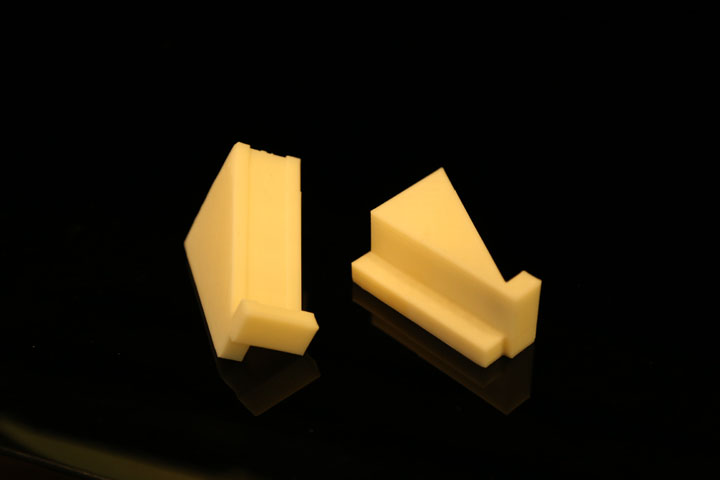

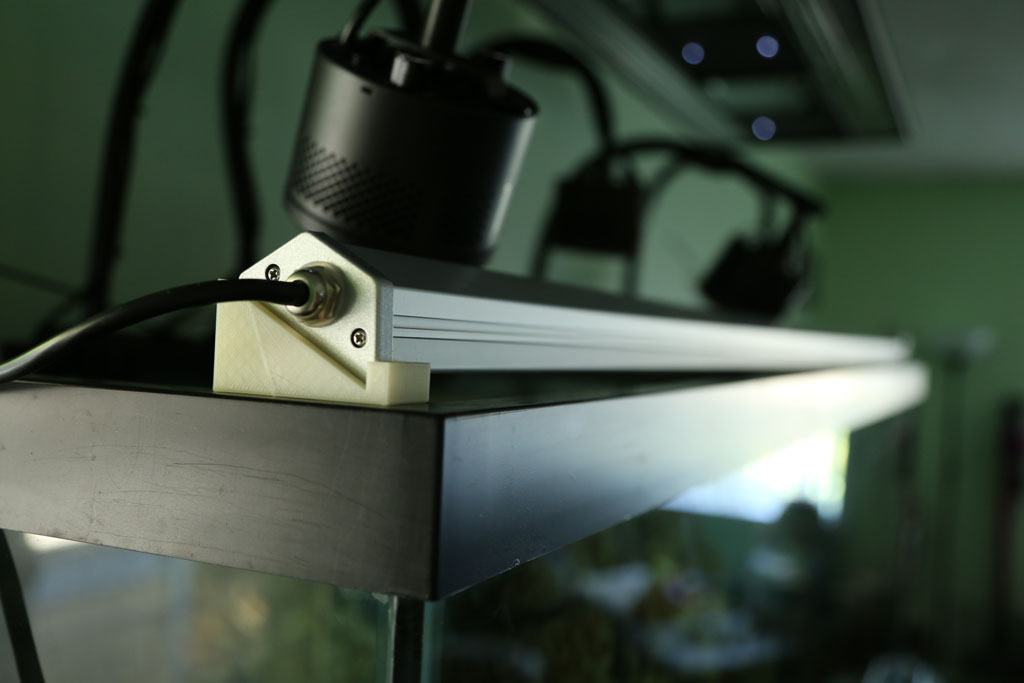

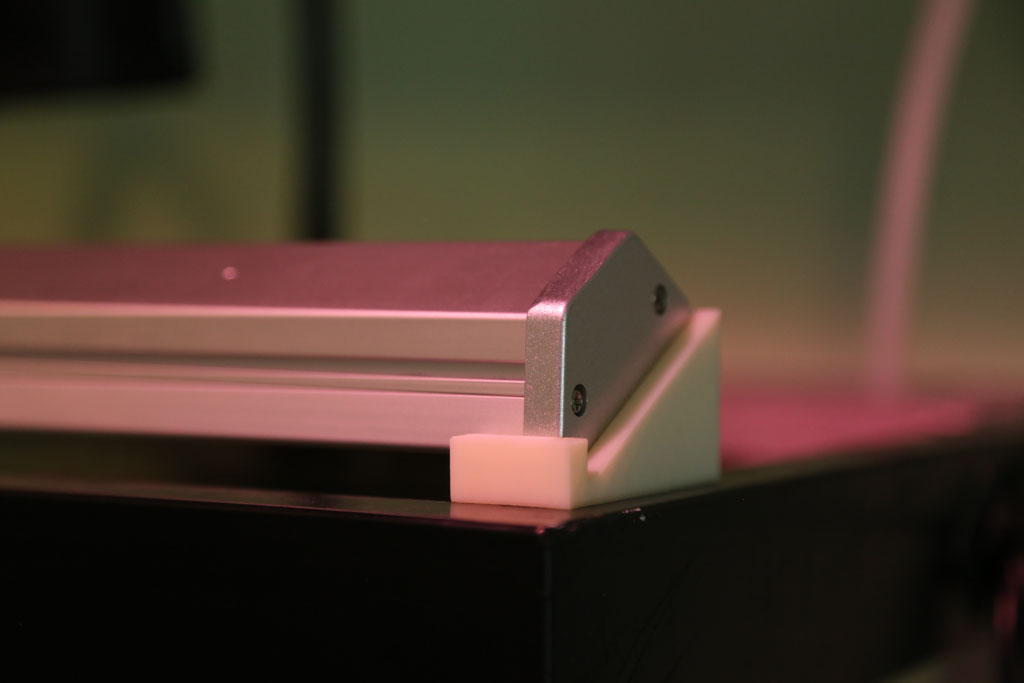

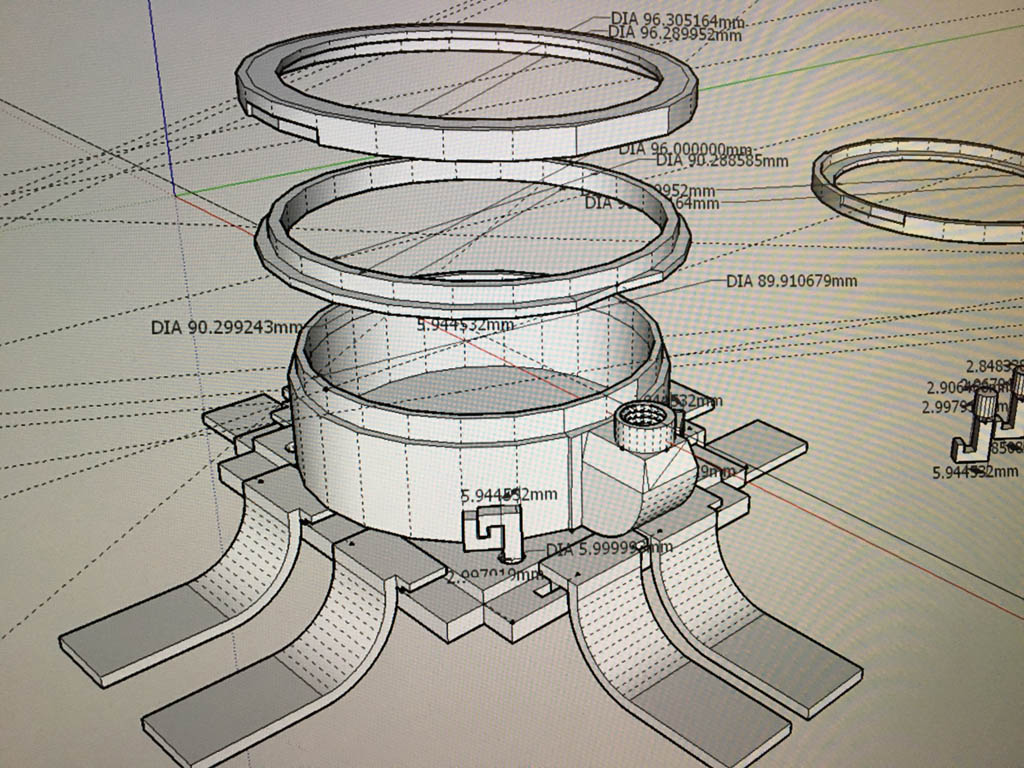

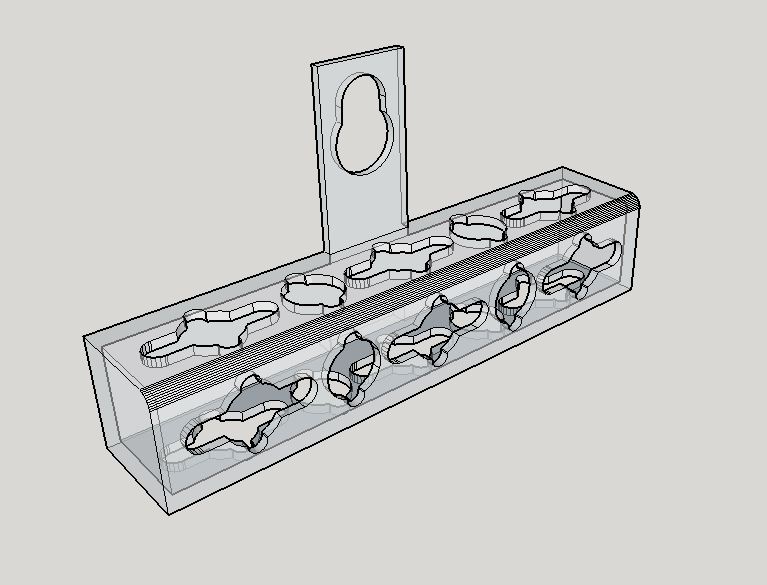

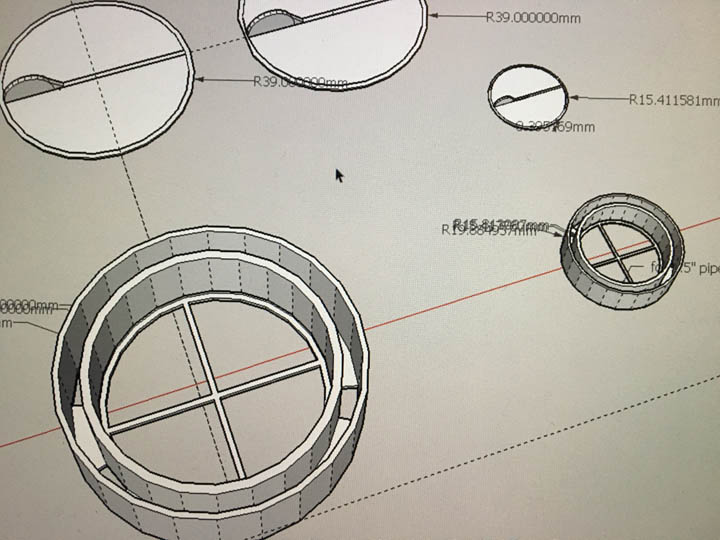

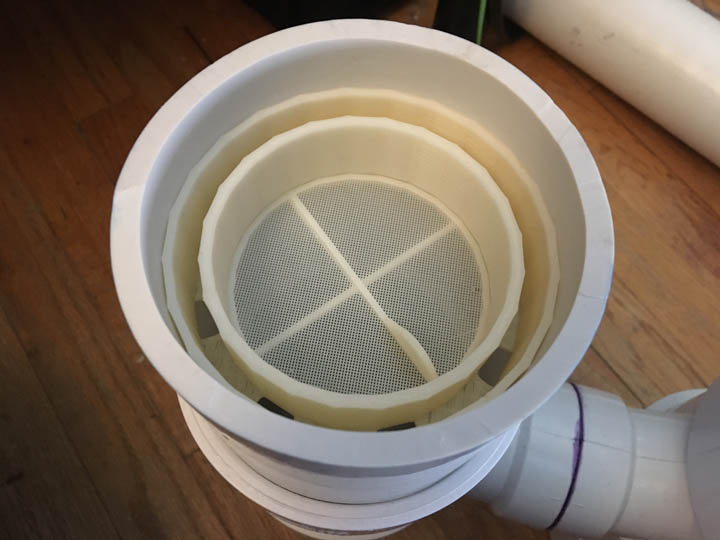

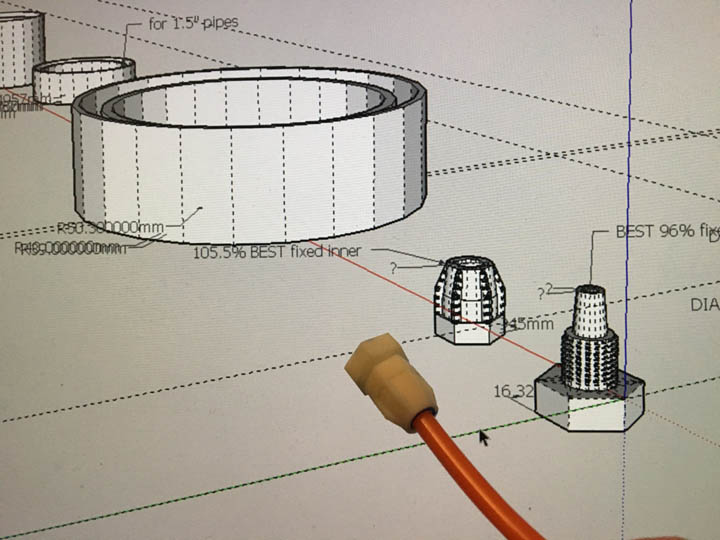

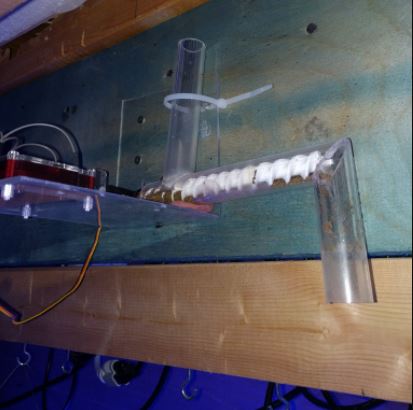

Below is what mine looks like. As you can see, I used acrylic tubing and an acrylic shelf to mount everything, and really streamlined the design. I get about two months of feeding with the top, vertical tube filled (12 fish, most are around 2", like a chromis and a damsel).

Initially, I programmed the adruino at a fixed rate of feeding every day. This worked well, but ended up being way too much food. So I adjusted the program and that helped a bit, but then I wanted to feed less, multiple times a day. So instead of having to constantly compile the adriuno code when ever I wanted to adjust the feeding amount, I build a serial protocol so I could control the feed from a computer (a Raspberry Pi in my case). So I send the command 'feed1' for about 20 pellets, or 'feed2' for 30 and so on, (up to 9, which is way way too much food, lol). This also allows me to get feedback (emailed updates) to ensure the feed command is at least running.

However, this is still a bit unstable if something disrupts the power (i.e. brownouts cause the arduino to reboot), then the serial connection drops and the feeding stops. So I have to manually re-establish the connection. Granted this only happens every few months, it is still a pain. The tank went for several weeks (not sure how much exactly, but long enough that my foxface started to slim down a bit) without the feeding running last spring. So, obviously that is unacceptable. My plan is to move the servo over to the raspberry pi (the pi controls a webcam on the tank and I have a few sensors to add to it anyway) and remove the adruino from the equation.

That said, once the arduino code is refined and if you never need to adjust it, it is a rock solid way to run a feeder like this. Otherwise, you could put a door on the output to regulate/adjust the feed. Assuming you use pellets; flakes would jam it up for sure.

Lastly, my auger has a longer pitch (more rotations), which (theoretically) allows for a more precise movement of the food.