- Joined

- Jul 11, 2018

- Messages

- 70

- Reaction score

- 84

Ok everyone, I know that you all may think this is a bit over engineered. However, I have been going nuts trying to get my ph up but I have a desktop tank and I do not have the space for a huge BRS reactor or the like so I set out to build a nano CO2 Reactor.

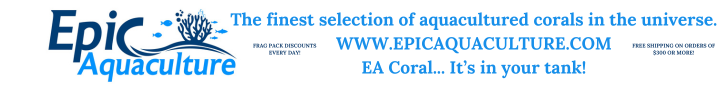

I started with a reactor that I found on Amazon as my base.

Some 1/4" (6mm) OD sturdy airline tubing

Some sponges

and some push-connect fittings for RODI lines

I already had the IceCap K1-nano skimmer on my tank

totaling out to about $40 USD.

The reactor fits perfectly into an Innovative Marine reactor clamp used for their desktop in-tank equipment. So this is how I mounted it to the side of my tank.

I decided to design a recirculating scrubber so that I had an additional amount of control other than turning the skimmer on or off. This is what the push connectors are for. Out of the package that I ordered I only needed the "T" fitting and the ball valve. The reactor comes with push connect fittings for RODI lines so I didn't have to bother with it.

I started by cutting generous amounts of the airline tubing to fit the space I have.

I used clear airline so that I could easily observe if there was excessive moisture in the line that could potentially melt the media inside of the reactor and cause a lot of problems. I also positioned the "T" fitting in the way that I did in order to allow a small slump in the airline, thus preventing any water from directly going into the reactor chamber and allowing for not only an outside air intake, but a quick let-off valve if I notice any liquid in the line.

the line that does NOT attach to the ball valve will go into the skimmer cap. I had to widen the hole a slight amount for the airline to fit snugly into the cap with minimal gaps.

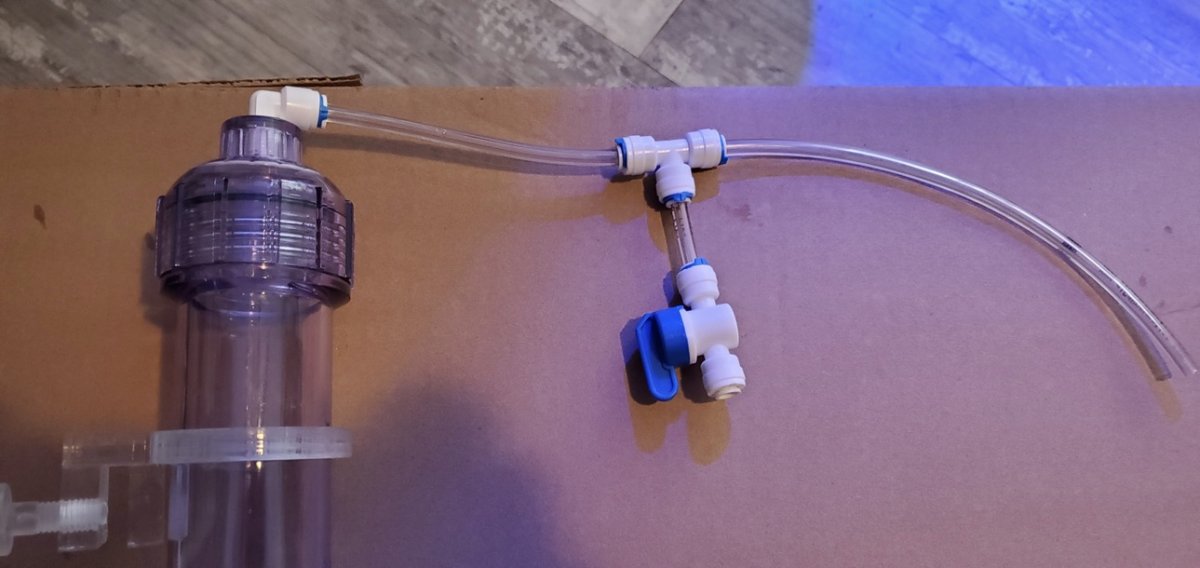

Now, there is the concern that bubbles will form at the mouth of the air intake inside of the skimmer lid and cause excessive moisture in the lines and in the chamber. To prevent this, I took one of the sponges and cut it up into small chunks about 1.5cm x 1.5cm. I then took an knife and poked a hole half way through one side so that the airline can fit into the hole and be covered after being inserted into the skimmer cap.

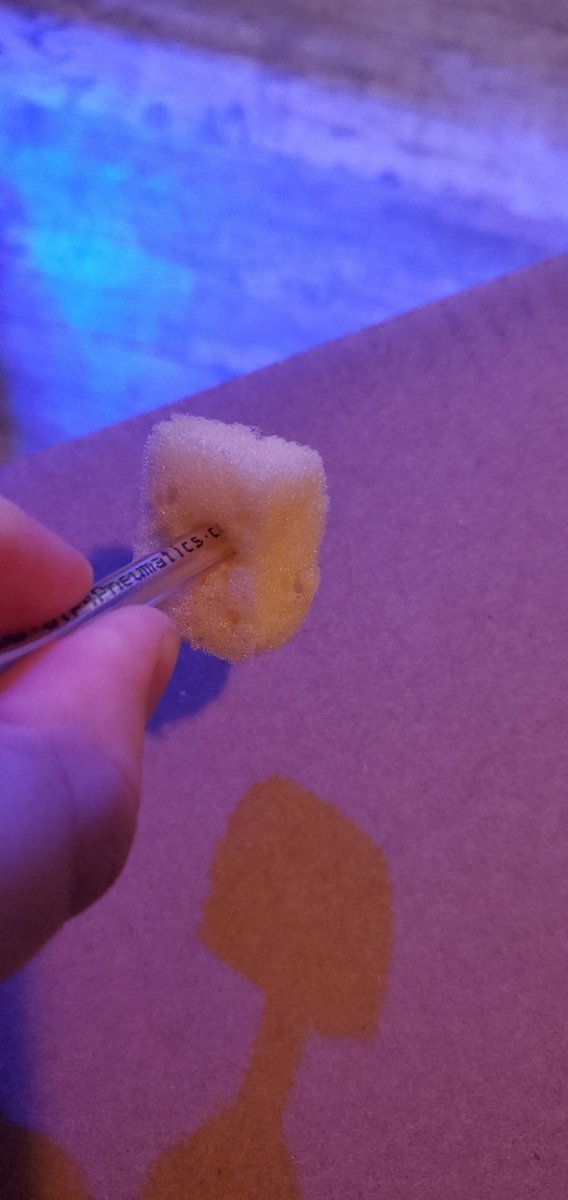

After this there was the touchy bit of how to get the airline to attach to the skimmer muffler. The IceCap doesn't have a piped intake like most skimmer mufflers do. So, I designed one to be 3D printed that you can download here. You should not need to modify the file at all. Other than adding supports for your particular brand of printer. I printed this on my resin printer the Creality LD-002R. Since this part will not be in water, I am not concerned with toxicity or leeching into the tank (although, I don't think that would be an issue anyways if it is properly cured)

This model was designed to fit into the stock intake tubing that goes between the venturi attachment and the muffler. So there shouldn't be any modification to your skimmer at all. The trick to this muffler is the intake pipe. The inside diameter of the intake pipe is 6mm (1/4") to snugly fit the airline tubing. This will allow for easy disassembly during maintenance, changing media, etc.

While that was printing I took the top off of the reactor and put it face down on top of one of the sponges and cut it to size to fit in the bottom of the reactor. Most CO2 media doesn't work as efficiently, or at all, if there is a lack of a small amount of moisture. This sponge will be a great way to prevent the media from melting and causing problems while still maintaining a small amount of moisture in the reaction chamber. The sponge also is an extra barrier to the thin filter provided with the reactor.

After the print on the muffler finishes I will continue the post!

I started with a reactor that I found on Amazon as my base.

Some 1/4" (6mm) OD sturdy airline tubing

Some sponges

and some push-connect fittings for RODI lines

I already had the IceCap K1-nano skimmer on my tank

totaling out to about $40 USD.

The reactor fits perfectly into an Innovative Marine reactor clamp used for their desktop in-tank equipment. So this is how I mounted it to the side of my tank.

I decided to design a recirculating scrubber so that I had an additional amount of control other than turning the skimmer on or off. This is what the push connectors are for. Out of the package that I ordered I only needed the "T" fitting and the ball valve. The reactor comes with push connect fittings for RODI lines so I didn't have to bother with it.

I started by cutting generous amounts of the airline tubing to fit the space I have.

I used clear airline so that I could easily observe if there was excessive moisture in the line that could potentially melt the media inside of the reactor and cause a lot of problems. I also positioned the "T" fitting in the way that I did in order to allow a small slump in the airline, thus preventing any water from directly going into the reactor chamber and allowing for not only an outside air intake, but a quick let-off valve if I notice any liquid in the line.

the line that does NOT attach to the ball valve will go into the skimmer cap. I had to widen the hole a slight amount for the airline to fit snugly into the cap with minimal gaps.

Now, there is the concern that bubbles will form at the mouth of the air intake inside of the skimmer lid and cause excessive moisture in the lines and in the chamber. To prevent this, I took one of the sponges and cut it up into small chunks about 1.5cm x 1.5cm. I then took an knife and poked a hole half way through one side so that the airline can fit into the hole and be covered after being inserted into the skimmer cap.

After this there was the touchy bit of how to get the airline to attach to the skimmer muffler. The IceCap doesn't have a piped intake like most skimmer mufflers do. So, I designed one to be 3D printed that you can download here. You should not need to modify the file at all. Other than adding supports for your particular brand of printer. I printed this on my resin printer the Creality LD-002R. Since this part will not be in water, I am not concerned with toxicity or leeching into the tank (although, I don't think that would be an issue anyways if it is properly cured)

This model was designed to fit into the stock intake tubing that goes between the venturi attachment and the muffler. So there shouldn't be any modification to your skimmer at all. The trick to this muffler is the intake pipe. The inside diameter of the intake pipe is 6mm (1/4") to snugly fit the airline tubing. This will allow for easy disassembly during maintenance, changing media, etc.

While that was printing I took the top off of the reactor and put it face down on top of one of the sponges and cut it to size to fit in the bottom of the reactor. Most CO2 media doesn't work as efficiently, or at all, if there is a lack of a small amount of moisture. This sponge will be a great way to prevent the media from melting and causing problems while still maintaining a small amount of moisture in the reaction chamber. The sponge also is an extra barrier to the thin filter provided with the reactor.

After the print on the muffler finishes I will continue the post!