- Joined

- Apr 30, 2016

- Messages

- 1,129

- Reaction score

- 374

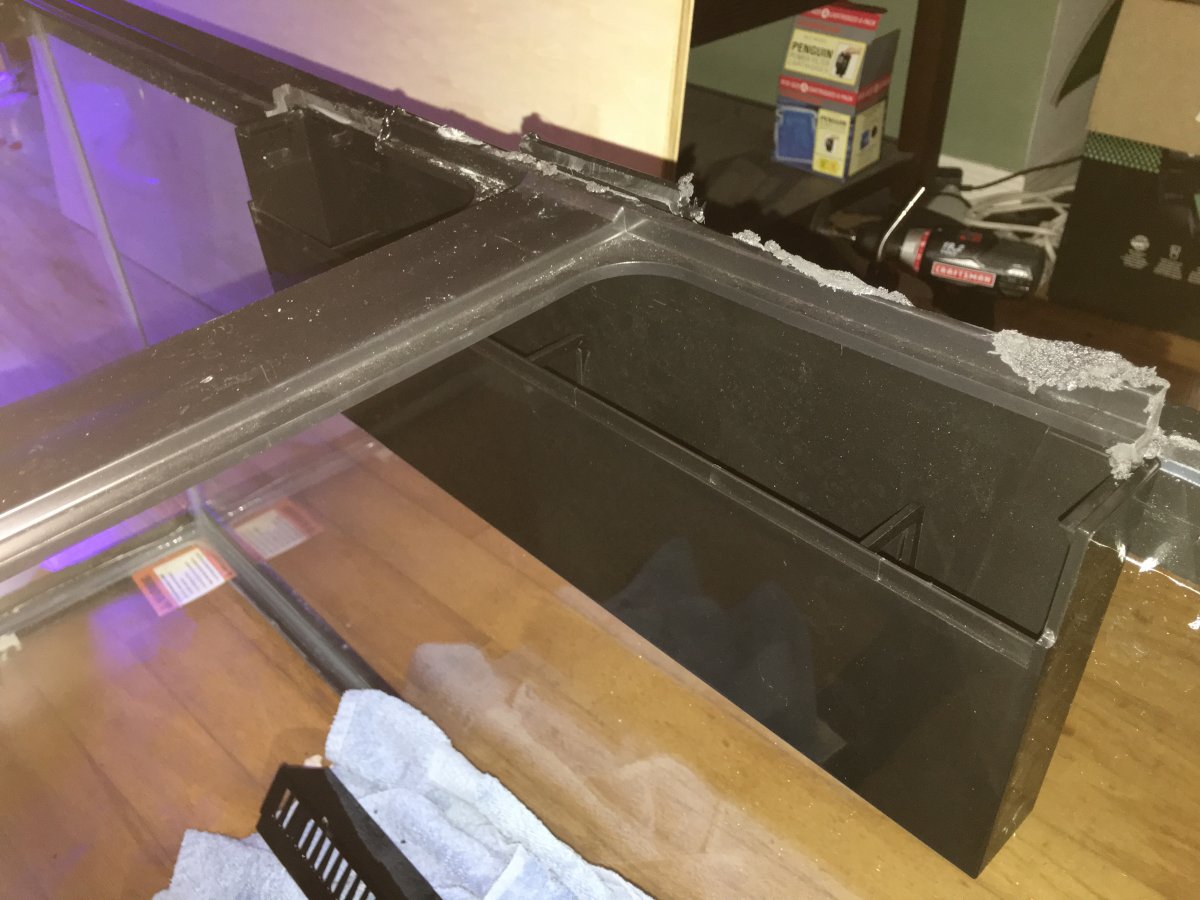

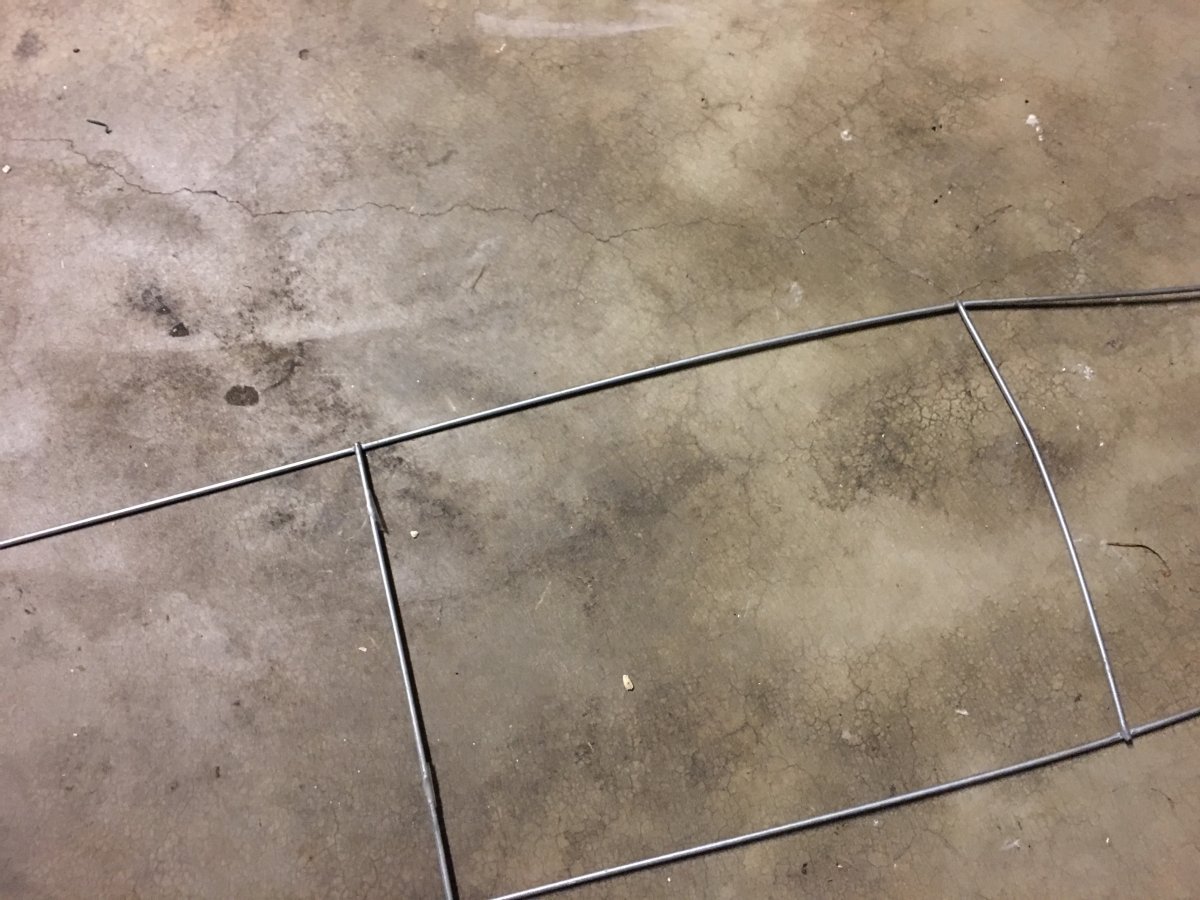

Hey. Soooooo I drilled a shade high even tho I checked it. So I cut the back and cleaned it and now it seals and no issue also the teeth slide out as it is. So how would u guys re attach the top support 2 the side. I plan on heating up some rod like I did 2 find it’s depth b4 sinking a wheel into it. So I can melt both edges 2gather. Will it make the plastic brittle like I’m thinking? So I’ll inforce it ima cut it just 2 where it webs out then the other pic shows how I’d reinforce and re mold it 2gather. And prolly use a epoxy over it 2 ensure all the holes are bonded. Thx!!!!!!