Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reefer 750 XXL

- Thread starter Fringe09

- Start date

- Tagged users None

Users Who Are Viewing This Thread (Total: 1, Members: 0, Guests: 1)

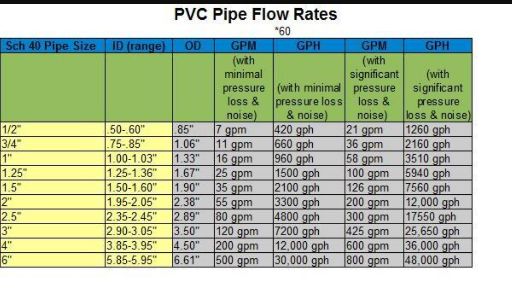

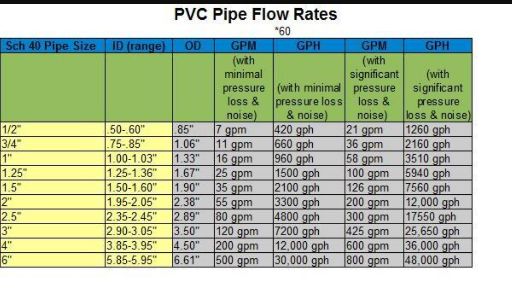

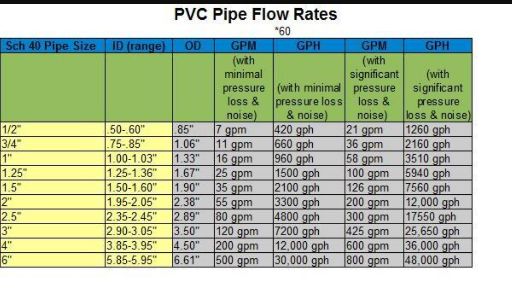

Dang , 1/2 in return looks restricting.

eh.. I've seen so many different charts with different measurements on it. This chart shows the max flow is around 1410. The return is the same piping as the 525 and 450, so about 3/4 inch.Dang , 1/2 in return looks restricting.

Is that the tank weight, or shipping weight for the whole package?Well, I at least know the tank weight now. 540 is more than I thought it would weigh.

- Joined

- Oct 1, 2016

- Messages

- 82

- Reaction score

- 51

@Dawsokj1988 how's the assembly coming along? I'm dying to hopefully get to pick mine up next weekend!

- Joined

- Jun 8, 2017

- Messages

- 1,420

- Reaction score

- 790

How's the stand build coming along? The stands come with that extra piece as I've seen in other builds.

I'm upgrading from a 350, so it's going to go a bit slow. I'm also going to spend some time modifying the cabinet (thank you Broadfield for the inspiration). I won't be throwing the cabinet doors on for a while, but the cabinet itself is complete. The interesting thing about the bottoms of the cabinets is there's potential to attach some heavy duty wheels to the boards to create a "slide out" option (this is all theoretical).

- Joined

- Jun 25, 2017

- Messages

- 125

- Reaction score

- 66

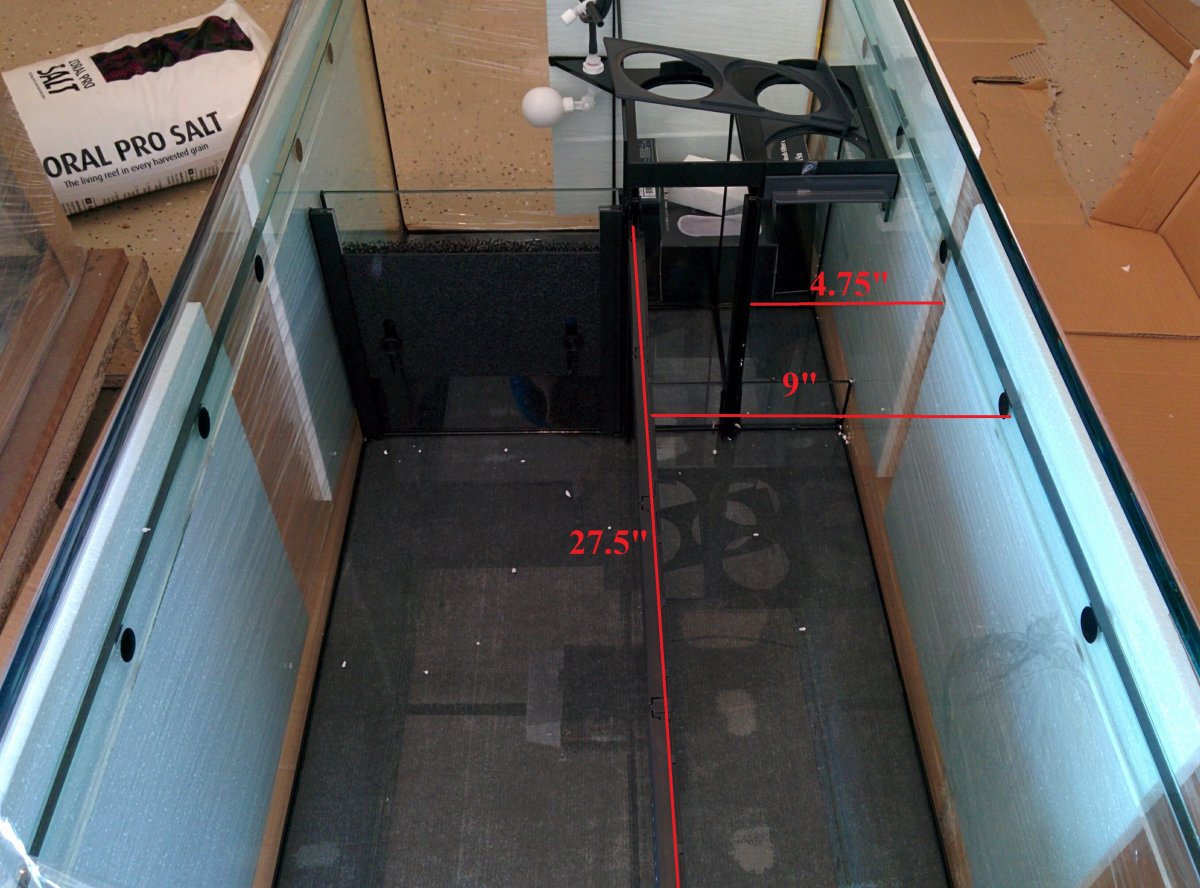

That sump is a lot bigger than I had thought it would be. Can't wait to see pics of the tank. What's the overall impression of quality?

Well, I currently own a 350 so it's on par with it. If you've never owned a Reefer before, well then you're in for a treat. They're known to be some of the highest quality "non-custom" tanks available.

Broadfield

Red Sea Reefer Consultant... Non Affiliated

View BadgesExcellence Award

Reef Of The Month

Photo of the Month

Reef Squad Emeritus

Midwest Reefer

Alright, so just to clarify a few things: the 750 uses the same plumbing sizes as the 350, 450, etc... I took the return nozzle from my 350 and hooked it up to the 750 and it fit perfectly. I also took a 3/4 inch MPT and confirmed that it screws in perfectly to the end of the return line (the barb fitting screws out). If wanting to hard plumb to the return line, there's no need to buy a metric conversion because a standard 3/4 inch female fitting screws into the end of the return line.

I skimmed through @Broadfield 's post and unless I'm mistaken, he doesn't know what his return flow is due to having his L1 run multiple reactors as well.

I'd like to believe that the return line can handle more than 600 gph lol. The recommended pump size on Red Sea's website is 1850 gph (for the 750 xxl). @RedSeaKev is this flow rate achievable in the 750 xxl? I'm trying to rationalize why the same plumbing would be used on a tank that's twice the size.

I do not run any sort of flow monitoring. I will eventually, but more so for the reactors. I run a Vectra L1 at 100%, through a plumbing setup with a lot of elbows and three reactors, and I have more flow at the return nozzle than what most people run. I have experimented with running the L1 around 50% and I still had adequate flow through the sump. Hope this helps.

- Joined

- Jun 8, 2017

- Messages

- 1,420

- Reaction score

- 790

Nice.

I thought the same thing when assembling my 525XL... I got an extra trim piece of the opposite color as well. Maybe they meant to do this? Not sure why! Good luck with the new tank, I'm sure it's going to be awesome!

Pretty sure they did it to save packaging costs between the black and the white cabinets. So all black cabinets come with the bottom white trim piece regardless.

- Joined

- Jun 8, 2017

- Messages

- 1,420

- Reaction score

- 790

I'll be running the fmk with a Varios 8 so we'll see what we can crank out with two reactors and maybe the top off

Converted to a fuge.

Converted to a fuge.

- Joined

- Jun 8, 2017

- Messages

- 1,420

- Reaction score

- 790

I'll be running the Varios 8 as well, though I'm debating whether or not to throw on a GHL flow meter.

Are you finish plumbing it yet?

Haven't started. Going nice and slow with this build. Right now I'm working in a cad program to try and figure out what I want to do with the dry side of the cabinet. I have my 350 to tide me over in the mean time. Here's the first iteration of what I'm thinking.Are you finish plumbing it yet?

- Joined

- Jun 8, 2017

- Messages

- 1,420

- Reaction score

- 790

Looks like a good start. Will that be a 4-head doser on the left?

They threw in an extra piece.. It's the wrong color though lol

Pretty sure thats just something they use w/ packaging. I had one leftover after my 250 assembly albeit much much smaller

PS: congrats on having the 1st we've seen!!