redfishbluefish

Stay Positive, Stay Productive

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Article Contributor

NJRC Member

Hospitality Award

My Tank Thread

I think I'm finished summarized what's occurred with my build since 2008. If I can think of anything I've missed, I'll be sure to add it. I want to be able to revisit this thread in the future and see the changes that have occurred.

So from here on, this will be current....as the changes/improvements continue with my build. There is always something that needs to be done.

Here is my current "To Do" list:

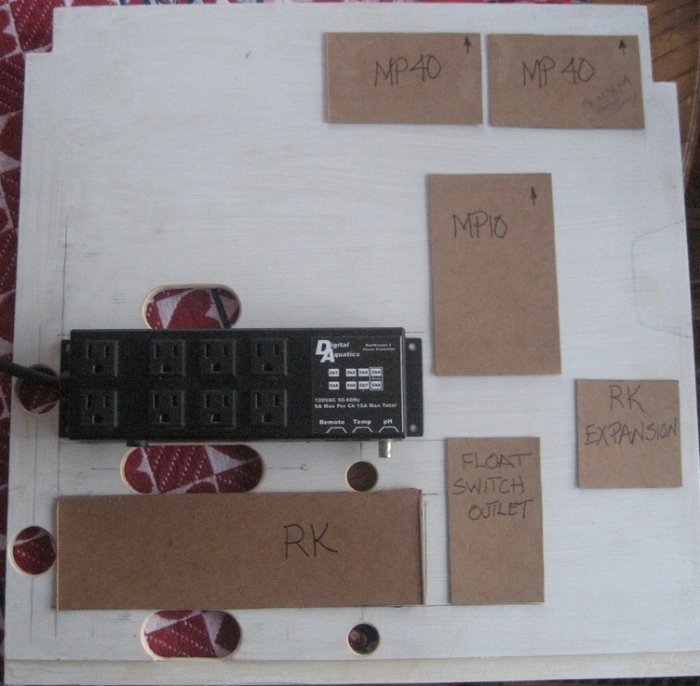

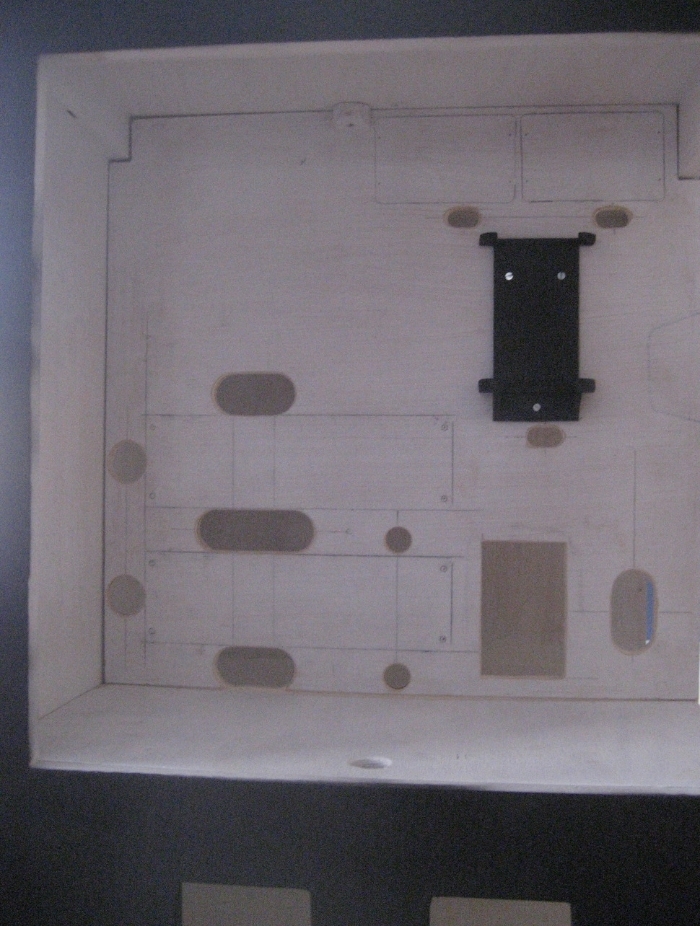

1. Build Equipment Cabinet (for the last 7 years!!!)

2. Repaint the stand and canopy flat black.

3. Purchase and install a DC return pump.

4. Continue to kick around the idea of a manifold (for the carbon reactor and biopellet reactor)

5. Mull over adding an Algae Scrubber....design and location considerations

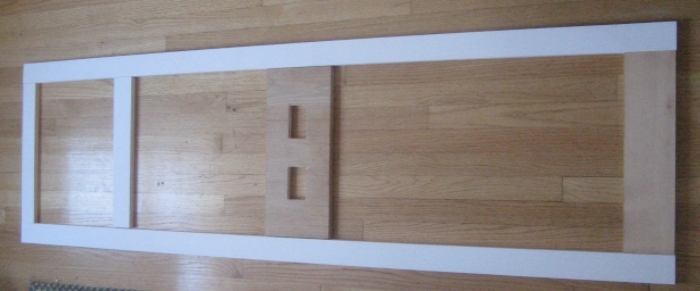

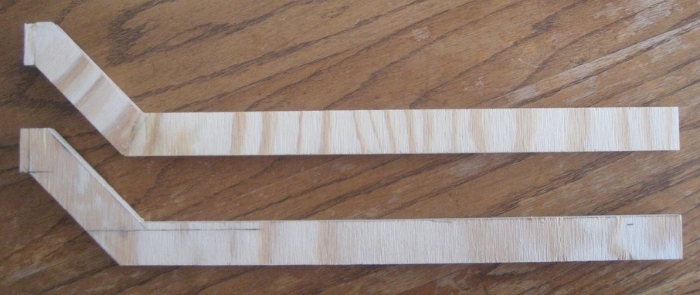

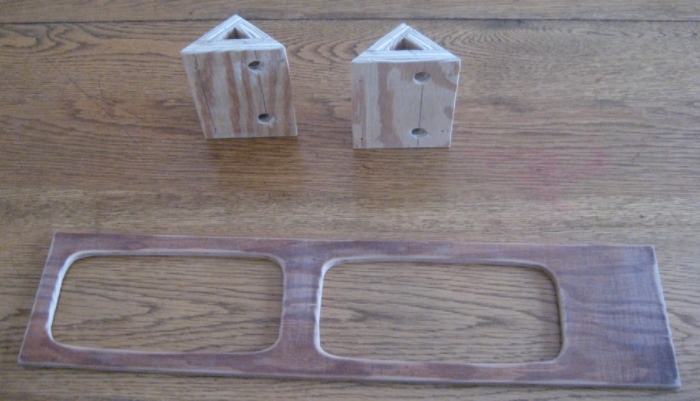

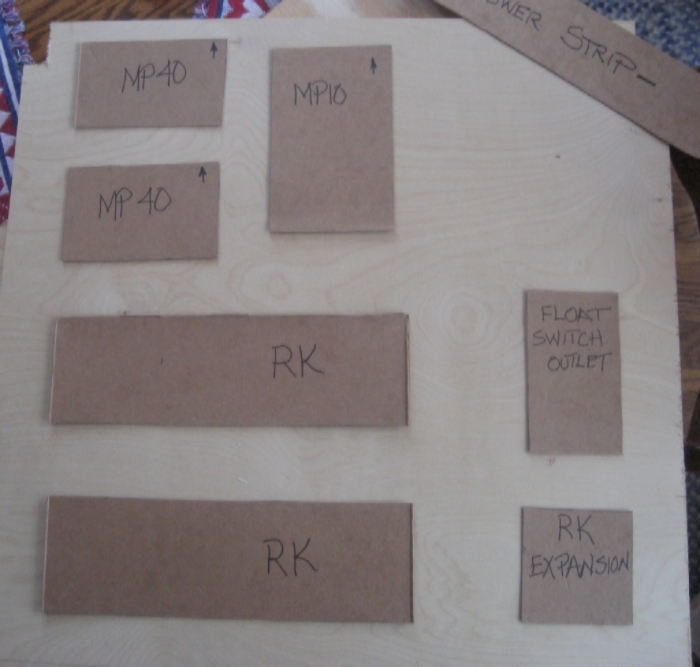

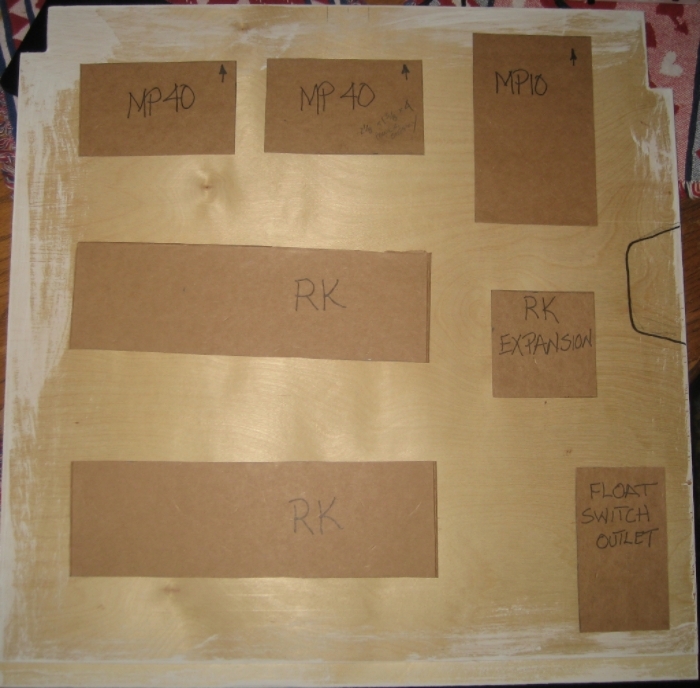

So tomorrow is a fresh day to tackle my list....beginning with the equipment cabinet....long overdue. I've pulled out the side boards I cut years ago, and they have a warp to them. I also started a DIY thread on this that I'll move over to this thread.

So from here on, this will be current....as the changes/improvements continue with my build. There is always something that needs to be done.

Here is my current "To Do" list:

1. Build Equipment Cabinet (for the last 7 years!!!)

2. Repaint the stand and canopy flat black.

3. Purchase and install a DC return pump.

4. Continue to kick around the idea of a manifold (for the carbon reactor and biopellet reactor)

5. Mull over adding an Algae Scrubber....design and location considerations

So tomorrow is a fresh day to tackle my list....beginning with the equipment cabinet....long overdue. I've pulled out the side boards I cut years ago, and they have a warp to them. I also started a DIY thread on this that I'll move over to this thread.