redfishbluefish

Stay Positive, Stay Productive

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Article Contributor

NJRC Member

Hospitality Award

My Tank Thread

Miscellaneous Stuff (continued]

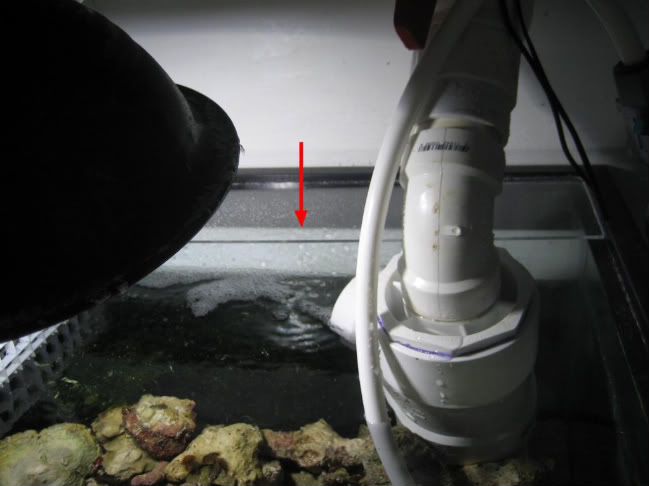

V. Saltwater Mixing

It's amazing what you do when you first start on this saltwater venture, and you try to save money. My first mixing container was a Rubbermaid Roughneck storage container. When filled with water, the sides would buldge out.

No problem....the water wasn't in there that long......until.....I was using the same container for storing towels out at the pool. After about three years, this container started to break apart. It became brittle and just fell apart. Granted, it was out in the sun, but I thought of the one I was using for water!

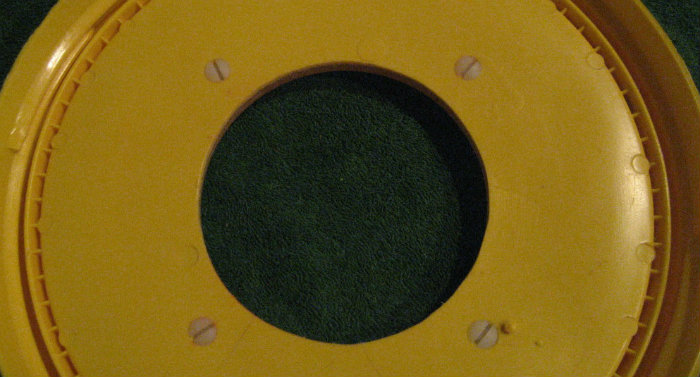

That's when I made the switch to Brute cans. First one was a 20 gallon to mix 15 gallons of new water....with a single Koralia K4.

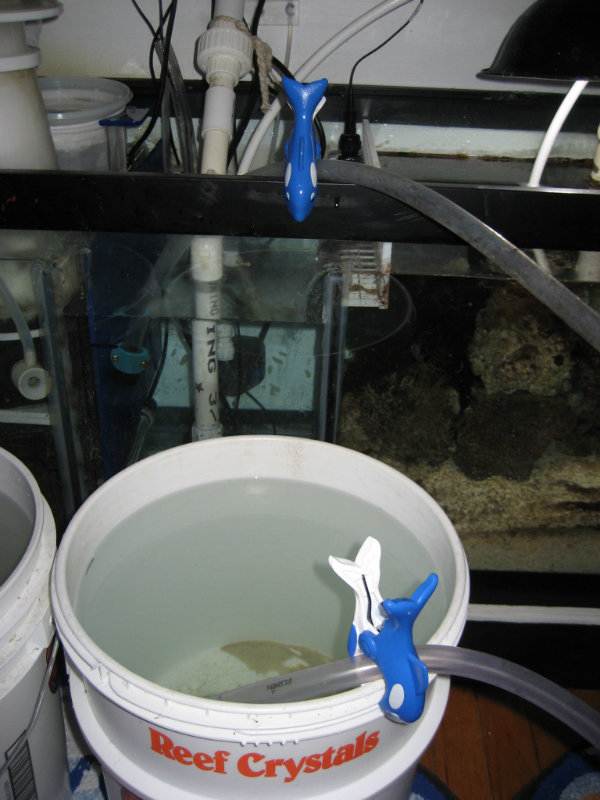

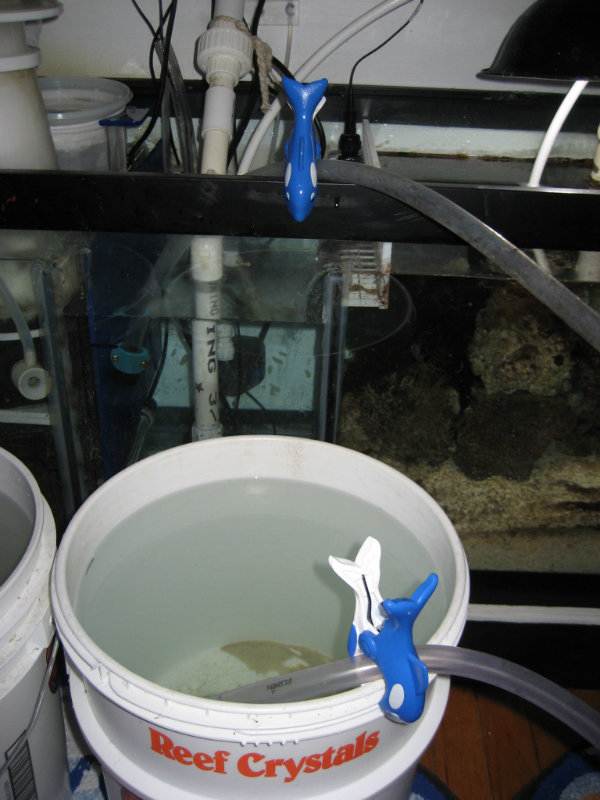

At this point I was still using old salt buckets to hold the "dirty" water that was being removed. Every week I'd fill up three salt buckets with old water to do a water change:

The weekly water changes just became too much. So I decided to do 25 gallons every two weeks. I couldn't do that in the 20 gallon Brute, so I picked up a 32 gallon Brute and add a Koralia K8 to help in mixing:

Using five salt buckets became old real fast for the old water, so I went out and picked up a second 32 gallon Brute. So one for making new water, and one for hauling away the old water.

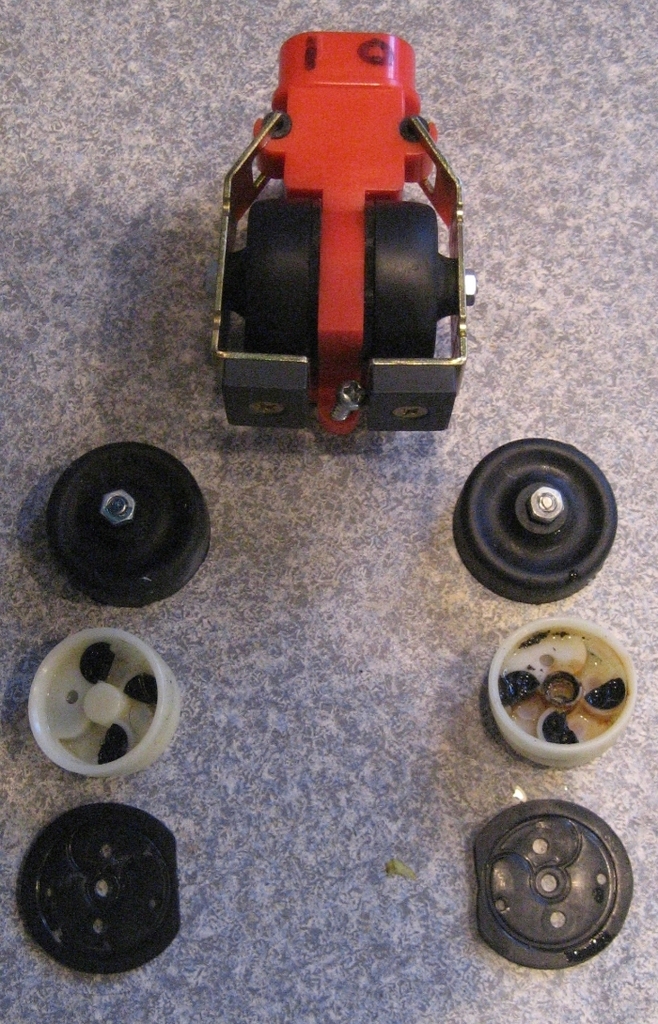

In addition, I picked up the dollies. These things are great. I can wheel around the new water and wheel around the old water. A little pricey, but I'd suggest getting the dollies as well.

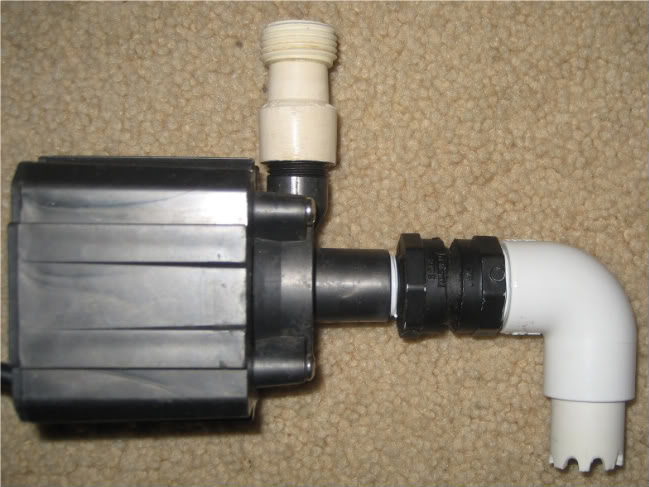

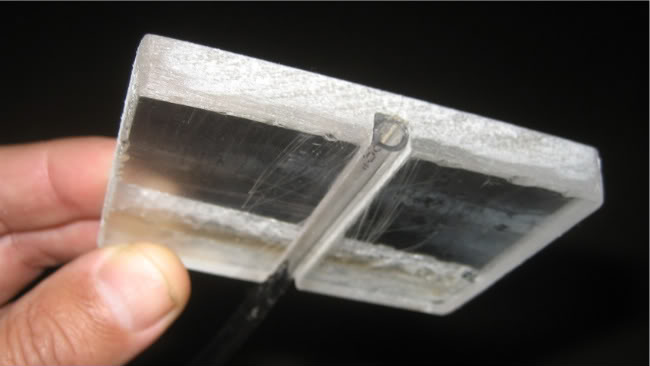

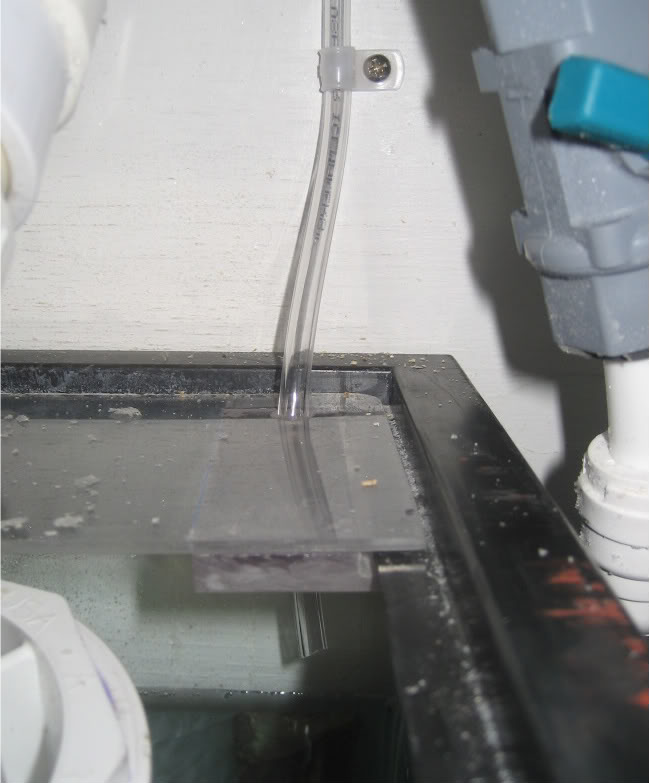

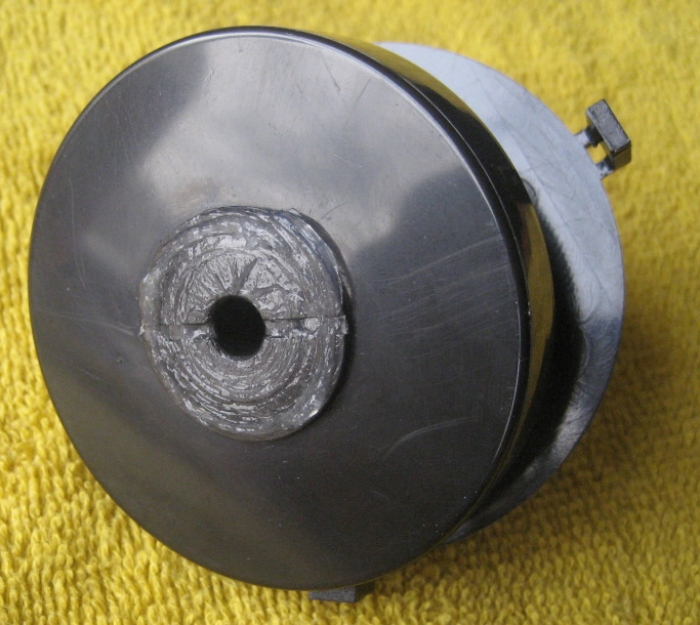

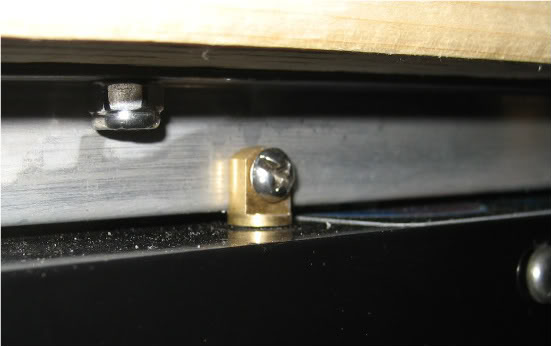

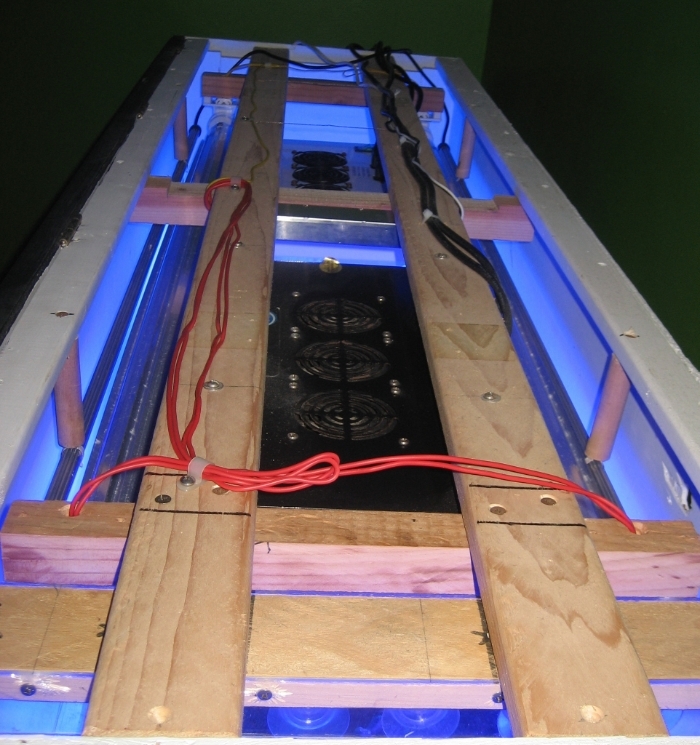

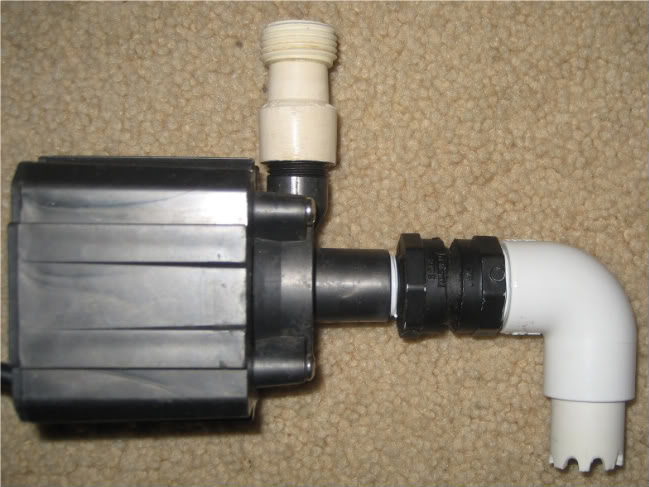

Finally, the water is pumped into the tank with a MAG7 with a DIY Rube Goldberg I put together to suck up the last drop, and a little adaptor to hook directly to a hose fitting.

V. Saltwater Mixing

It's amazing what you do when you first start on this saltwater venture, and you try to save money. My first mixing container was a Rubbermaid Roughneck storage container. When filled with water, the sides would buldge out.

No problem....the water wasn't in there that long......until.....I was using the same container for storing towels out at the pool. After about three years, this container started to break apart. It became brittle and just fell apart. Granted, it was out in the sun, but I thought of the one I was using for water!

That's when I made the switch to Brute cans. First one was a 20 gallon to mix 15 gallons of new water....with a single Koralia K4.

At this point I was still using old salt buckets to hold the "dirty" water that was being removed. Every week I'd fill up three salt buckets with old water to do a water change:

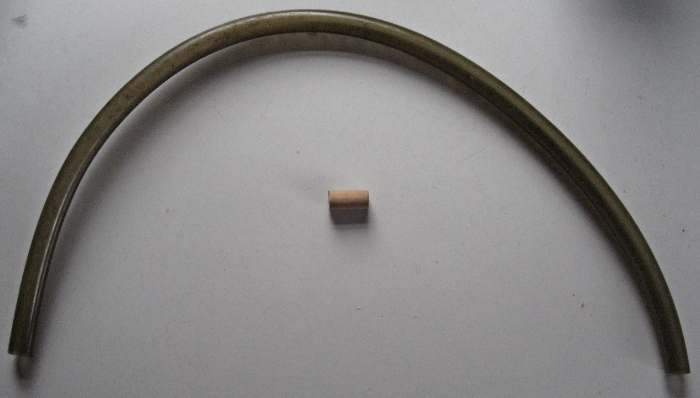

The weekly water changes just became too much. So I decided to do 25 gallons every two weeks. I couldn't do that in the 20 gallon Brute, so I picked up a 32 gallon Brute and add a Koralia K8 to help in mixing:

Using five salt buckets became old real fast for the old water, so I went out and picked up a second 32 gallon Brute. So one for making new water, and one for hauling away the old water.

In addition, I picked up the dollies. These things are great. I can wheel around the new water and wheel around the old water. A little pricey, but I'd suggest getting the dollies as well.

Finally, the water is pumped into the tank with a MAG7 with a DIY Rube Goldberg I put together to suck up the last drop, and a little adaptor to hook directly to a hose fitting.