I’m making a 36x21x36 stand for my 65 gallon rimless tank. I’m trying to make it good enough, but I’ve never done woodworking so I’m pretty new to this.

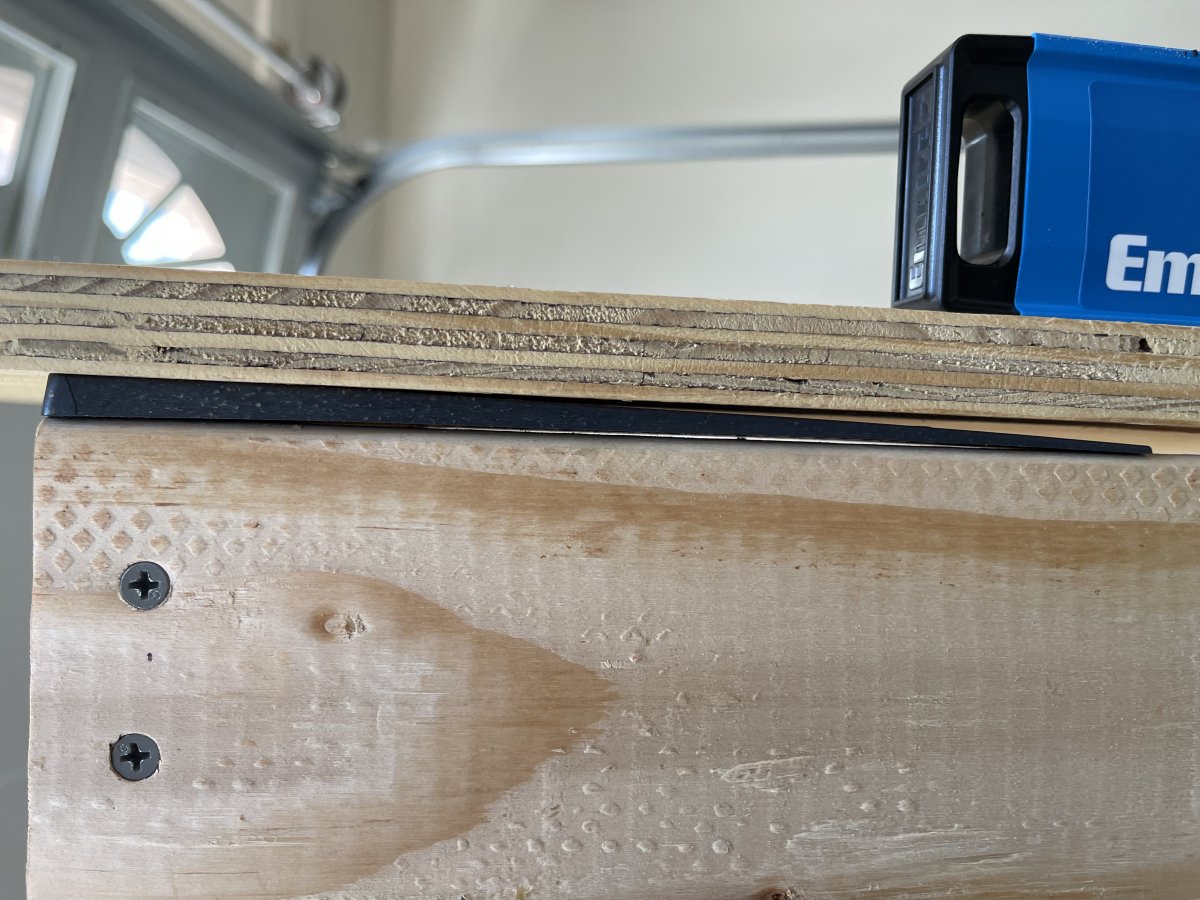

I made the frame based on Rocket Engineer’s design, but the top (or, if I turned it over, the bottom) is uneven. I’ve attached pictures here to show what I mean.

Would adding shims as shown in the pictures be acceptable? Or should I just start over and try to make the frame more level? The gap at the widest is going just over 3/8”.

I made the frame based on Rocket Engineer’s design, but the top (or, if I turned it over, the bottom) is uneven. I’ve attached pictures here to show what I mean.

Would adding shims as shown in the pictures be acceptable? Or should I just start over and try to make the frame more level? The gap at the widest is going just over 3/8”.