Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing thread

- Thread starter PurpleMonster

- Start date

- Tagged users None

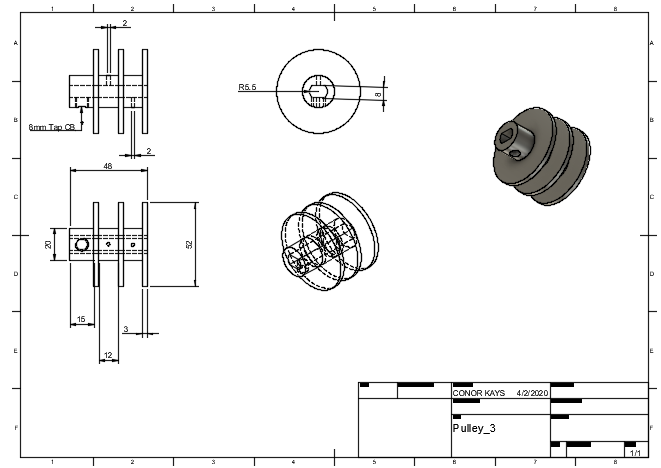

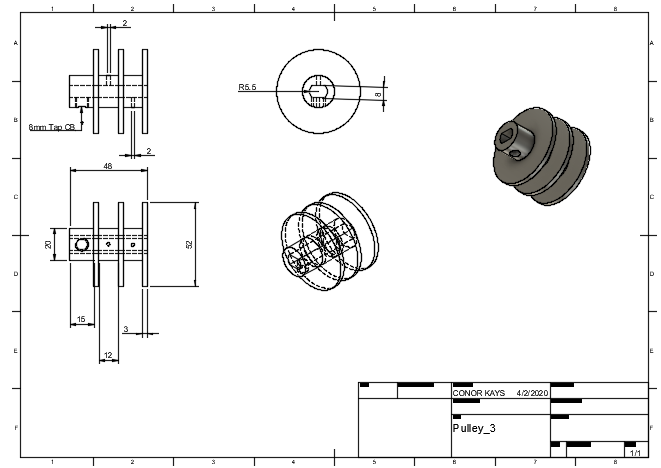

Alright, so here is what I came up with. Since I think I might be paying a shop to do this, I went all out.

I don't feel I can work with a 1" max diameter unfortunately. Just not enough material to get shaft and flanges etc in there.

So if anyone does think they can rock this out with aluminum, let me know. Or if anyone knows an online shop I could send this off for a quote on, that would be appreciated as well.

Call outs in mm, ended up being more precise after busting out the calipers.

Critique away:

Fusion Files

Note the keyed shaft is likely a second op when machining (can't turn a non-round on a lathe). There are a few online quoting services where you can dump them a model and see what they come back with.

I designed some overflow covers for the Deep Sea Aquatics Neo Nano 34g tank because it became a hassle constantly cleaning and having to find and cut new filter sponges that would fit properly. There was no significant change in noise from the overflow after switching to the covers.

https://www.thingiverse.com/thing:4259175

https://www.thingiverse.com/thing:4259175

- Joined

- Apr 1, 2018

- Messages

- 438

- Reaction score

- 388

You can have places like sculpteo.com print that out in titanium if you wanted.

Well I don't really need titanium, what material from their website would you guys recommend? Getting this turned in metal, as expected, seems to be more than I am willing to spend. I know the middle makes turning this tricky. I could change this, but on sculpteo with a "Nylon PA12 60u" material, I am comfortable with the price. Just not sure if it will hold up. SLS process is currently selected.

Thanks,

Conor

I guess I was just saying that you could get as exotic as you wanted to with printing it in metal.

I’m not familiar enough with SLS to know how durable it is. Order a backup though. I figure worse case If it breaks, there’s still a metal axle in the middle of the pulley

I’m not familiar enough with SLS to know how durable it is. Order a backup though. I figure worse case If it breaks, there’s still a metal axle in the middle of the pulley

Metal? Any aluminum.Well I don't really need titanium, what material from their website would you guys recommend? Getting this turned in metal, as expected, seems to be more than I am willing to spend. I know the middle makes turning this tricky. I could change this, but on sculpteo with a "Nylon PA12 60u" material, I am comfortable with the price. Just not sure if it will hold up. SLS process is currently selected.

Thanks,

Conor

SLS is more brittle than injection molding but can be pretty strong. Let me run a simulation to see what a solid nylon part would yield at.

Well I don't really need titanium, what material from their website would you guys recommend? Getting this turned in metal, as expected, seems to be more than I am willing to spend. I know the middle makes turning this tricky. I could change this, but on sculpteo with a "Nylon PA12 60u" material, I am comfortable with the price. Just not sure if it will hold up. SLS process is currently selected.

Thanks,

Conor

This simulation is a simple Stress Analysis in Inventor using a Nylon 6/6 (note, this is a much stronger material than the SLS nylon as its glass fiber reinforced) base from your drawing.

The pulley is fixed on the flat end - there is no shaft inserted into the pulley. Stresses are 30lb loads as bearing loads pulling left and right on the surface of the 2mm holes:

You have about 0.2mm of displacement (not a big deal in a plastic):

Stress is on the fixing hole:

Safety factor is 5 at the bearing/cord hole, which is enough (less than 1 is part failure under load, 1 is "just enough but any more will fail)

Note that Nylon 6/6 is a glass fiber reinforced plastic so its stronger than the quoted material. Conservative estimates using the material properties put the safety factor of the 2mm holes at 2x: https://www.sculpteo.com/en/materials/sls-material/plastic-material/ (running the sim with PC/ABS which is injection molded gives a safety factor of ~3.6x).

Will it work? Yeah, probably

Glad I discovered this thread.

I've always wanted to get into 3D printing, but doing my own designs would come later (once I learn)

Perfect thread to get some idea's and starter designs.

Now I got to read the whole thread hoping there is a recommended Printer and what material to use that is reef safe.

I've always wanted to get into 3D printing, but doing my own designs would come later (once I learn)

Perfect thread to get some idea's and starter designs.

Now I got to read the whole thread hoping there is a recommended Printer and what material to use that is reef safe.

- Joined

- Jun 19, 2017

- Messages

- 457

- Reaction score

- 152

Hello guys i pulled the plug on an ender 3 printer, and should arrive home in any moment, ive been watching videos on how to set it up and use it, can you guys point me in the right direction with some more videos and information i can read?

- Joined

- Oct 3, 2015

- Messages

- 740

- Reaction score

- 590

I just purchased a Ender 3 Pro. You will LOVE it! What a great printer for the price. I just printed a bracket for my G5 Blue to fit a Max Nano.

This YouTube link will help you set up the Ender to almost perfection on the print quality.

This YouTube link will help you set up the Ender to almost perfection on the print quality.

Your making this harder then it needs to be. Check out https://www.mcmaster.com/pulleys/belts-and-pulleys/. They have all sorts of pulleys available. There are other sources. I know in southern Ca McFadden-Dale hardware carries some. Just look up industrial hardware. I bet eBay and amazon have all sorts of them as well.Alright, so here is what I came up with. Since I think I might be paying a shop to do this, I went all out.

I don't feel I can work with a 1" max diameter unfortunately. Just not enough material to get shaft and flanges etc in there.

So if anyone does think they can rock this out with aluminum, let me know. Or if anyone knows an online shop I could send this off for a quote on, that would be appreciated as well.

Call outs in mm, ended up being more precise after busting out the calipers.

Critique away:

Fusion Files

- Joined

- Apr 1, 2018

- Messages

- 438

- Reaction score

- 388

Your making this harder then it needs to be. Check out https://www.mcmaster.com/pulleys/belts-and-pulleys/. They have all sorts of pulleys available. There are other sources. I know in southern Ca McFadden-Dale hardware carries some. Just look up industrial hardware. I bet eBay and amazon have all sorts of them as well.

I have been through Mcmaster extensively along with every other place on the internet. Nothing fits my needs well at all. Not to mention I really don't want zinc coated parts above the tank.

I just pulled the trigger at sculpteo. Went with the HP MJF process. $80 for two pieces that will be exactly what I want. No brainer. I really appreciate those of you that weighed in, pointed me towards design software/useful sites, and took the time to do drawings/run sims for me. I should have them in my hands in a week and will share the end results.

Cheers,

Conor

I have been through Mcmaster extensively along with every other place on the internet. Nothing fits my needs well at all. Not to mention I really don't want zinc coated parts above the tank.

I just pulled the trigger at sculpteo. Went with the HP MJF process. $80 for two pieces that will be exactly what I want. No brainer. I really appreciate those of you that weighed in, pointed me towards design software/useful sites, and took the time to do drawings/run sims for me. I should have them in my hands in a week and will share the end results.

Cheers,

Conor

Very curious how they turn out - thats one print process I haven't seen in person yet

- Joined

- Mar 27, 2018

- Messages

- 1,387

- Reaction score

- 762

Have any of y'all printed dosing containers?

Using Acrylic is definitely a better way to make a dosing container. 3D prints tend to not be water tight for one and are not clear. The only reason I can think to consider doing a 3D printed one would be if you wanted a weird shape.Have any of y'all printed dosing containers?

Agreed, the layers are not water tight, It would have to be pretty thick to achieve that.

- Joined

- Mar 27, 2018

- Messages

- 1,387

- Reaction score

- 762

Knowing my luck it would go as well as the pistol he printed a couple years ago lol.

Agreed, the layers are not water tight, It would have to be pretty thick to achieve that.

I can absolutely third using an acrylic, but 3d printing watertight is not hard to achieve, its possible you're just under-extruding. However, walls are much more likely to seal than floors for most FDM printers. If you use ABS, you can quickly solvent seal as well (slosh some acetone in the container).

- Joined

- Apr 1, 2018

- Messages

- 438

- Reaction score

- 388

Came out perfectly. I have zero concerns about the strength. Will be a couple weeks before I put this all together, but more updates to come!Very curious how they turn out - thats one print process I haven't seen in person yet

thanks again for all the input and help!

Similar threads

- Replies

- 2

- Views

- 79

- Replies

- 20

- Views

- 1,082

New Posts

-

-

-

-

What kind of pod are they and are they harmful to coral?

- Latest: EeyoreIsMySpiritAnimal