So this happened...

Santa brought me a ProStar Rimless 200 from ProClear Aquariums. Dimensions are 60" x 26" x 24", low-iron glass.

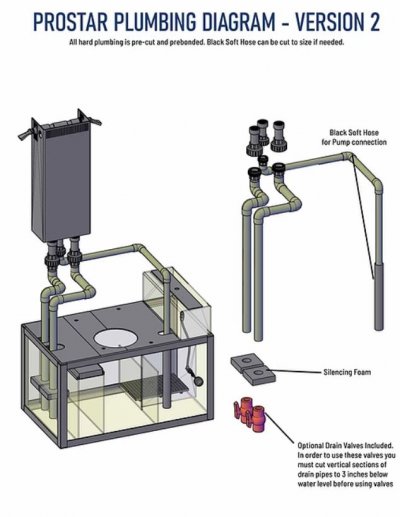

Stand is an aluminum frame, with glass doors on overlay hinges. Underneath is a 35G glass sump. Typical of tanks in this class (i.e. Waterbox), it comes pre-plumbed.

Santa is under the impression, apparently, that I have been very good.

If you've not been good, this tank is a steal, priced below the competitors in its class. I'm quite impressed, and chuffed beyond belief.

Architects are, in general, both creative and quite fussy. We like things precise. So come along with me on the build, and we'll see where it leads...

Santa brought me a ProStar Rimless 200 from ProClear Aquariums. Dimensions are 60" x 26" x 24", low-iron glass.

Stand is an aluminum frame, with glass doors on overlay hinges. Underneath is a 35G glass sump. Typical of tanks in this class (i.e. Waterbox), it comes pre-plumbed.

Santa is under the impression, apparently, that I have been very good.

If you've not been good, this tank is a steal, priced below the competitors in its class. I'm quite impressed, and chuffed beyond belief.

Architects are, in general, both creative and quite fussy. We like things precise. So come along with me on the build, and we'll see where it leads...