- Joined

- Nov 8, 2019

- Messages

- 220

- Reaction score

- 381

$99.00

$840.00

Ecotech.... Your prices and products suck...lol!

" A sucker is born every minute" -P.T. Barnum

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I don't want to derail either. I just remember dealing with their customer service on another product that didn't contain the right amount of components and customer service raked me over the coals to get extras sent out. It was not an expensive part and should not have been such a headache but definitely stuck with me. Hopefully their lighting division is different and autonomousDo tell?? Did you have a poor experience with a Gen 1 unit? I was hoping a big company like phillips would have good customer service.

Anyhow, dont want to derail the thread.

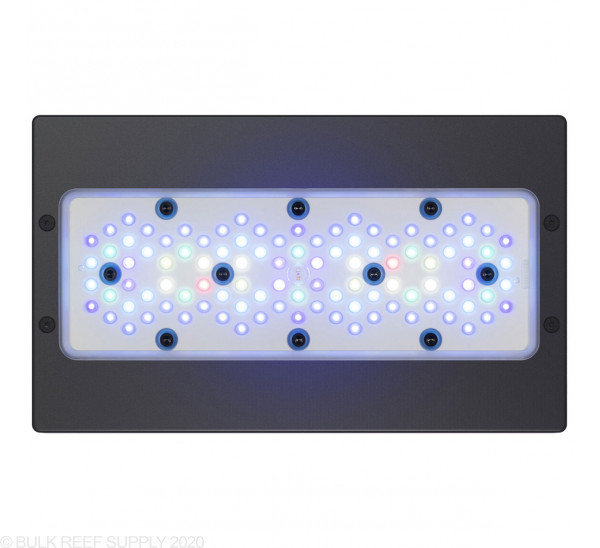

Its a combination of that hole being too close to the edge, the expansion of heat and then sudden cooling down... puts stress on that particular area... any type of plastic that thin will fail in that type of condition... lexan, nylon, plexi, delron, teflon, acrylic or torlon, are the only plastics I know that wouldn’t stress crack in that type of engineered construction under heating/cooling setting... a type of adjustable torque screwdriver on the lowest setting should be used with a type of light viscosity loctite should be used in that construction... the only fix I can see currently is an extended plate that over hangs the parameter of the light a 1/4” or even an 1/8” so it gives the surface area of the counter sink and plate enough pressure to rest on the base of the light without ruining the integrity of the plate itselfI would suggest that the torq of the fasteners, or the fastening system itself is the likely cause. That or they could simply change the material of the plastic cover slightly (different glass fill amount) to alter the strength or stiffness.

There are many solutions, but most will still fail if the attachment method is allowing excessive torque on those fasteners and therefore excessive compressive stress on that material. I also wonder, with UV LEDs right there, if UV embrittlement may occur over time to that plastic (obviously not the issue here since this is failure at the other end of the bell curve).

$99.00

$840.00

Ecotech.... Your prices and products suck...lol!

" A sucker is born every minute" -P.T. Barnum

Its a combination of that hole being too close to the edge, the expansion of heat and then sudden cooling down... puts stress on that particular area... any type of plastic that thin will fail in that type of condition... lexan, nylon, plexi, delron, teflon, acrylic or torlon, are the only plastics I know that wouldn’t stress crack in that type of engineered construction under heating/cooling setting... a type of adjustable torque screwdriver on the lowest setting should be used with a type of light viscosity loctite should be used in that construction... the only fix I can see currently is an extended plate that over hangs the parameter of the light a 1/4” or even an 1/8” so it gives the surface area of the counter sink and plate enough pressure to rest on the base of the light without ruining the integrity of the plate itself

Ecotech makes products for a hobby bud... we make steam turbines for Fuji, Toshiba, mitsubishi etc... that exceed speeds of 3500 rpm putting hundreds of lives at risk... not talking ****, but just sayin’ Hahaha... so yes, my thoughts don’t matter, but they are theoretically the cheapest options that I could think of... we make more costly life saving decisions on $1-5 mill product, not ideas for $500-$1k hobby lights... so yes, I guess you are correct... hahahaha... okay, im done ranting...Hexy those are likely solutions, but I disagree with your comment about any plastic failing in that use case, there are a solid selection of injection moldable materials that can withstand significant stress.

Anyhow, like you said, there are smart folks at Ecotech and I imagine they can cook through this fast, with or without our advise.

My turbines go 4000Ecotech makes products for a hobby bud... we make steam turbines for Fuji, Toshiba, mitsubishi etc... that exceed speeds of 3500 rpm putting hundreds of lives at risk... not talking ****, but just sayin’ Hahaha... so yes, my thoughts don’t matter, but they are theoretically the cheapest options that I could think of... we make more costly life saving decisions on $1-5 mill product, not ideas for $500-$1k hobby lights... so yes, I guess you are correct... hahahaha... okay, im done ranting...

I know i know... im tired and sensitive right now...My turbines go 4000

Assuming the plastic is not the issue I would just make the holes in it larger and use rubber grommets inserted into the holes. that way it can expand and contract without stressing the plastic.

I even found a video from the 23.03 so this has been known to Ecotech for quit some time but didn't matter to openly comment on this issue.Kind of surprised ecotech hasnt responded here yet. I dont agree with them just sending out replacement housings and having people fix them themselves. That would be like a customer coming in to the dealership with a new sierra, saying their radio is broken and us just giving them a radio. Also looks like the bolts are over torqued.

I even found a video from the 23.03 so this has been known to Ecotech for quit some time but didn't matter to openly comment on this issue.