This is my first DIY stand build thread. I built this stand a couple years ago and am finally getting around to writing it up.

Some background first. At the beginning of the pandemic my company sent us all home and I have been working remote since. As part of fitting out my office I decided to setup an unused 40 breeder I had laying around as a mixed reef. I have kept freshwater tanks and a FOWLR tank for years. I decided to do a reef to add to the, uhhhh, ambience in my office. Knowing I wanted a stand that was both functional and looked good I came to the conclusion DIY was my best bet.

I preface the remainder by saying I started with the idea I would save money. That is in fact untrue. I ended up spending about $150; I could have bought a prefab stand for somewhere in that price range so if you are looking to save money you probably can but don’t be disappointed if you don’t.

I also made some minor mistakes which I will point out as I post things. Nothing major and the finished product turned out both functional and I think looks pretty good for what I was trying to accomplish.

With that we begin

Materials list

2 x 4’s

1/4” birch sheeting

Trim/finish boards

Polyurethane black paint

Killz primer

Liquid nails

Wood and deck screws

Finish Nails

Cordless drill

Circular saw

Carpentry clamps

Level

Square

Immediately there are 2 minor mistakes. Firstly, I used construction grade 2 x 4’s. I recommend against this. Finish grade are much straighter. This did not cause any real issues for me but made it more difficult to gat the finish work square.

My second mistake here was using stainless steel wood screws. While they are perfectly fine from a strength and functionality standpoint I quickly realized after stripping the head on every third screw my mistake. Changing course to stainless steel deck screws fixed this.

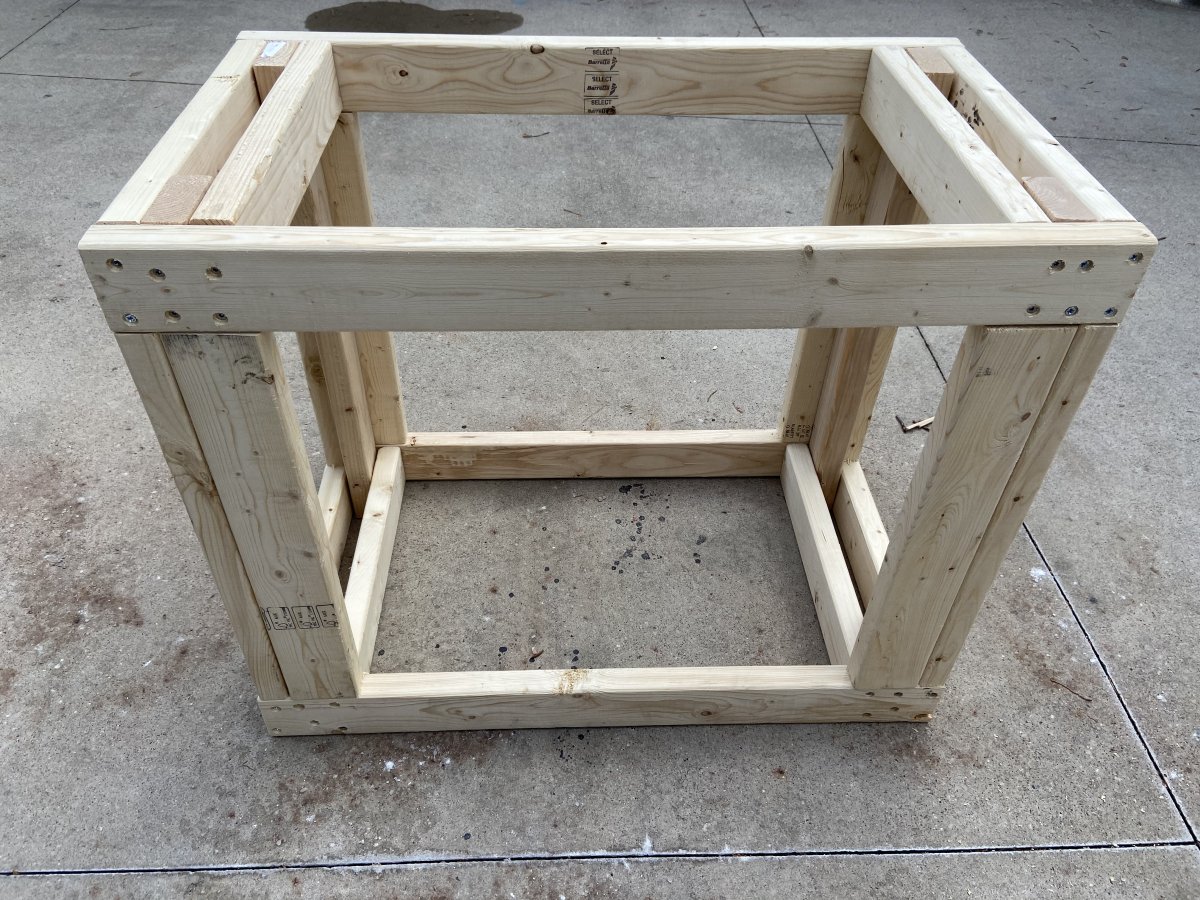

I don’t have pictures of everything but I do have the frame boards.

I’m somewhat of a planner for this kind of project so I laid the frames out prior to construction

I next secured the frames. This is straight forward although besides the screws I put a thin strip of Liquid nails. A completely unnecessary step but since my wife was concerned with strength I added that step. Happy wife happy life.

I decided to counter sink the screws for a cleaner finish. Also, prior to securing your corners ensure you square them up as much as possible. You will thank yourself later.

Next attach your supports. I used a single support in each corner then added an L brace outside to distribute the weight.

Single corner supports

Added cross bracers

All pieces are once again secured with deck screws and liquid nails.

I next added the L braces to each corner

And added cross braces to the floor.

I ensured everything was level at this point

And cross braces to the top and installed the floor

Note the cross braces above the floor. My original plan was to install recessed panels on the sides. I quickly decided to just “skin” the sides. Point being those cross braces are completely unnecessary.

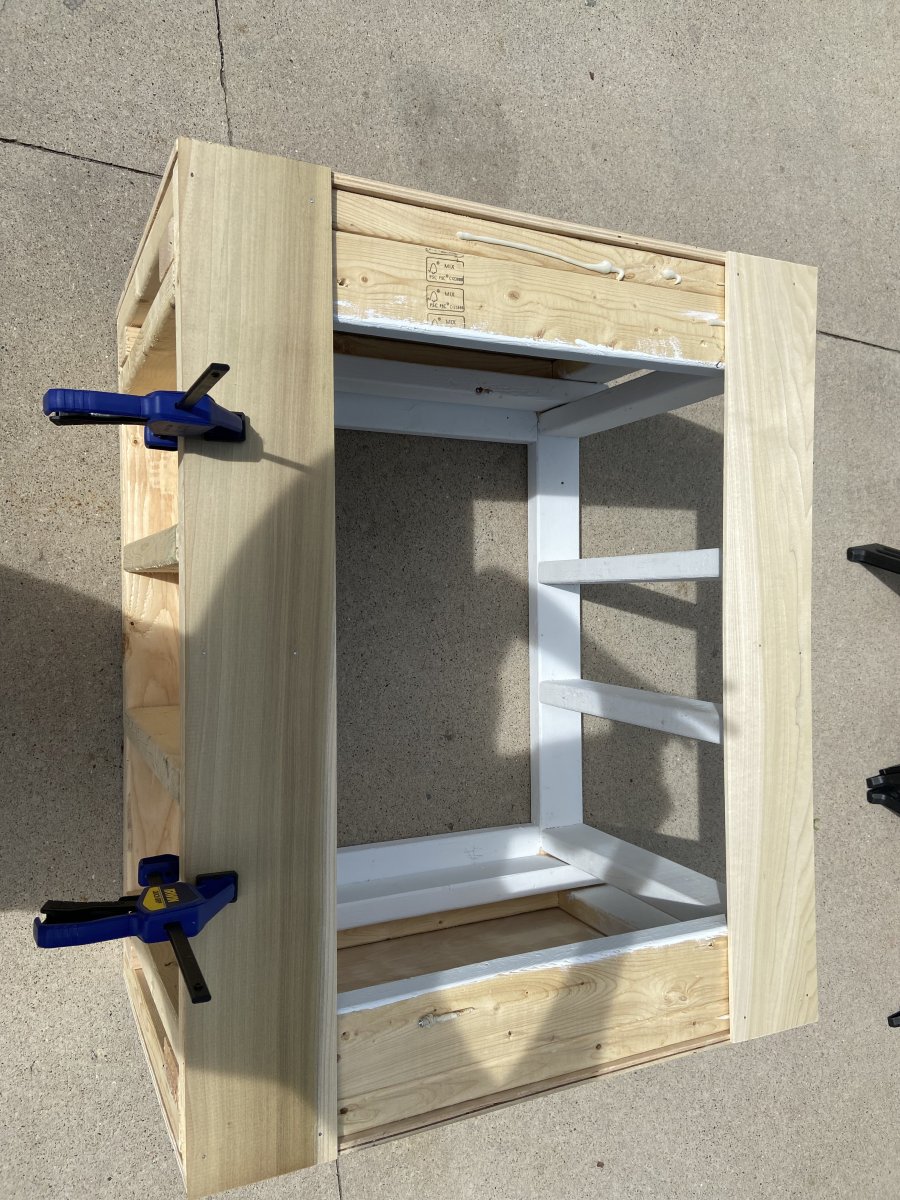

I next skinned the sides. Cut and attach the birch pieces using liquid nails and finish nails.

I next applied Killz to the inside of the stand. There are 2 reasons for this. First, using the polyurethane base will help with moisture wrecking the stand. Second, the bright white helps tremendously with seeing things when you’re working inside it.

Note that I applied Killz prior to skinning the front. I did this to ease the painting process and to not get splatter/runoff/drips onto the front skin.

Attach the skin to the front, again using liquid nails and finish nails

I clamped the skin to allow the liquid nails to dry. I likely don’t need the finish nails but again, to appease my lovely wife, I added them to ensure a secure fit.

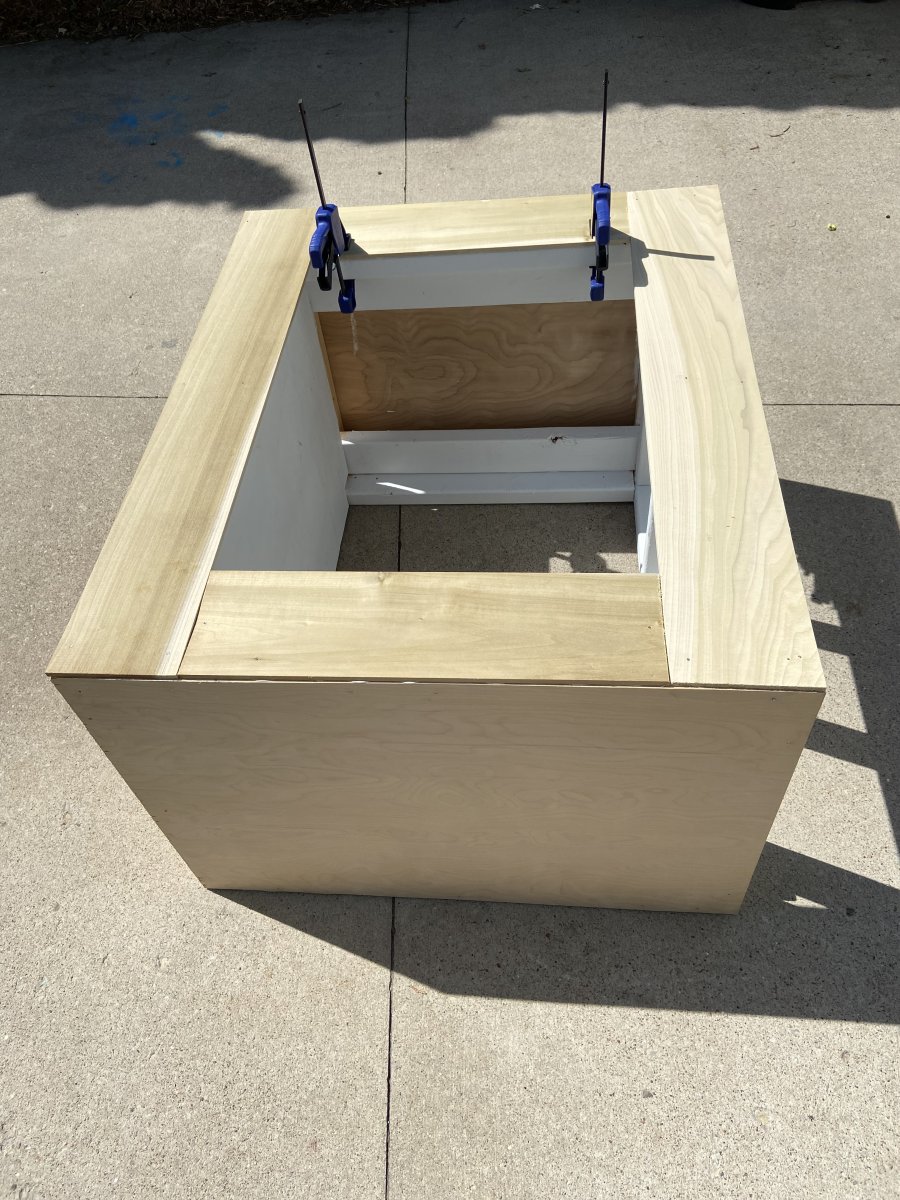

Finished stand prior to painting.

Next I included my wife by having her paint. She’s better at it than I am. I don’t have pictures of this step but it’s painting. We used a flat black polyurethane based spray paint from Krylon. I’m sure there are better alternatives but the key take away here is to use something non-toxic that will stand up to moisture and salt creep.

Finally, the finished product, in the office with the tank, sump, and components installed.

You can see from the last photo I have since replaced the original sump.

I will point out one last “mistake”. The stand is longer front to back than I’d like. Originally I intended to install a flat top. I decided against this, a result of using construction grade lumber. That lumber caused slightly unsquare finishes and while I had options to correct that, the tank sits level on the stand without the top. This in no way impacts function or detracts from the aesthetics so I rolled with it.

Some take always for the next build.

As noted, finish grade lumber. I’ll pay more but not enough to offset the issues the lower quality stuff causes.

As this stand will support the weight of a smart car I would eliminate some bracing. This thing is waaaaaaay overbuilt.

I would consider a more “screwless” design instead using biscuit joins and liquid nails. I have to explore this idea more and I‘m not sure I have the skills to pull it off but the idea intrigues me.

Install LED lights around the top of the interior. Not needed for any practical reason but would help with sight inside the cabinet and just looks cool

I would resurrect recessed side panels. Again, no functional reason, they just look cool.

This is a very basic design from a somewhat unhandy IT nerd. If I can build so can you!

Happy DIYing and reefing!!!

Some background first. At the beginning of the pandemic my company sent us all home and I have been working remote since. As part of fitting out my office I decided to setup an unused 40 breeder I had laying around as a mixed reef. I have kept freshwater tanks and a FOWLR tank for years. I decided to do a reef to add to the, uhhhh, ambience in my office. Knowing I wanted a stand that was both functional and looked good I came to the conclusion DIY was my best bet.

I preface the remainder by saying I started with the idea I would save money. That is in fact untrue. I ended up spending about $150; I could have bought a prefab stand for somewhere in that price range so if you are looking to save money you probably can but don’t be disappointed if you don’t.

I also made some minor mistakes which I will point out as I post things. Nothing major and the finished product turned out both functional and I think looks pretty good for what I was trying to accomplish.

With that we begin

Materials list

2 x 4’s

1/4” birch sheeting

Trim/finish boards

Polyurethane black paint

Killz primer

Liquid nails

Wood and deck screws

Finish Nails

Cordless drill

Circular saw

Carpentry clamps

Level

Square

Immediately there are 2 minor mistakes. Firstly, I used construction grade 2 x 4’s. I recommend against this. Finish grade are much straighter. This did not cause any real issues for me but made it more difficult to gat the finish work square.

My second mistake here was using stainless steel wood screws. While they are perfectly fine from a strength and functionality standpoint I quickly realized after stripping the head on every third screw my mistake. Changing course to stainless steel deck screws fixed this.

I don’t have pictures of everything but I do have the frame boards.

I’m somewhat of a planner for this kind of project so I laid the frames out prior to construction

I next secured the frames. This is straight forward although besides the screws I put a thin strip of Liquid nails. A completely unnecessary step but since my wife was concerned with strength I added that step. Happy wife happy life.

I decided to counter sink the screws for a cleaner finish. Also, prior to securing your corners ensure you square them up as much as possible. You will thank yourself later.

Next attach your supports. I used a single support in each corner then added an L brace outside to distribute the weight.

Single corner supports

Added cross bracers

All pieces are once again secured with deck screws and liquid nails.

I next added the L braces to each corner

And added cross braces to the floor.

I ensured everything was level at this point

And cross braces to the top and installed the floor

Note the cross braces above the floor. My original plan was to install recessed panels on the sides. I quickly decided to just “skin” the sides. Point being those cross braces are completely unnecessary.

I next skinned the sides. Cut and attach the birch pieces using liquid nails and finish nails.

I next applied Killz to the inside of the stand. There are 2 reasons for this. First, using the polyurethane base will help with moisture wrecking the stand. Second, the bright white helps tremendously with seeing things when you’re working inside it.

Note that I applied Killz prior to skinning the front. I did this to ease the painting process and to not get splatter/runoff/drips onto the front skin.

Attach the skin to the front, again using liquid nails and finish nails

I clamped the skin to allow the liquid nails to dry. I likely don’t need the finish nails but again, to appease my lovely wife, I added them to ensure a secure fit.

Finished stand prior to painting.

Next I included my wife by having her paint. She’s better at it than I am. I don’t have pictures of this step but it’s painting. We used a flat black polyurethane based spray paint from Krylon. I’m sure there are better alternatives but the key take away here is to use something non-toxic that will stand up to moisture and salt creep.

Finally, the finished product, in the office with the tank, sump, and components installed.

You can see from the last photo I have since replaced the original sump.

I will point out one last “mistake”. The stand is longer front to back than I’d like. Originally I intended to install a flat top. I decided against this, a result of using construction grade lumber. That lumber caused slightly unsquare finishes and while I had options to correct that, the tank sits level on the stand without the top. This in no way impacts function or detracts from the aesthetics so I rolled with it.

Some take always for the next build.

As noted, finish grade lumber. I’ll pay more but not enough to offset the issues the lower quality stuff causes.

As this stand will support the weight of a smart car I would eliminate some bracing. This thing is waaaaaaay overbuilt.

I would consider a more “screwless” design instead using biscuit joins and liquid nails. I have to explore this idea more and I‘m not sure I have the skills to pull it off but the idea intrigues me.

Install LED lights around the top of the interior. Not needed for any practical reason but would help with sight inside the cabinet and just looks cool

I would resurrect recessed side panels. Again, no functional reason, they just look cool.

This is a very basic design from a somewhat unhandy IT nerd. If I can build so can you!

Happy DIYing and reefing!!!

Last edited: