- Joined

- Mar 15, 2020

- Messages

- 68

- Reaction score

- 33

Hi All,

What I thought to be a simple maintenance seems to have become more complicated. I have a 4-stage BRS RODI filter system that has been running well for about a year. In the last few weeks its been producing 2 TDS water and I could tell the resin was on the way out.

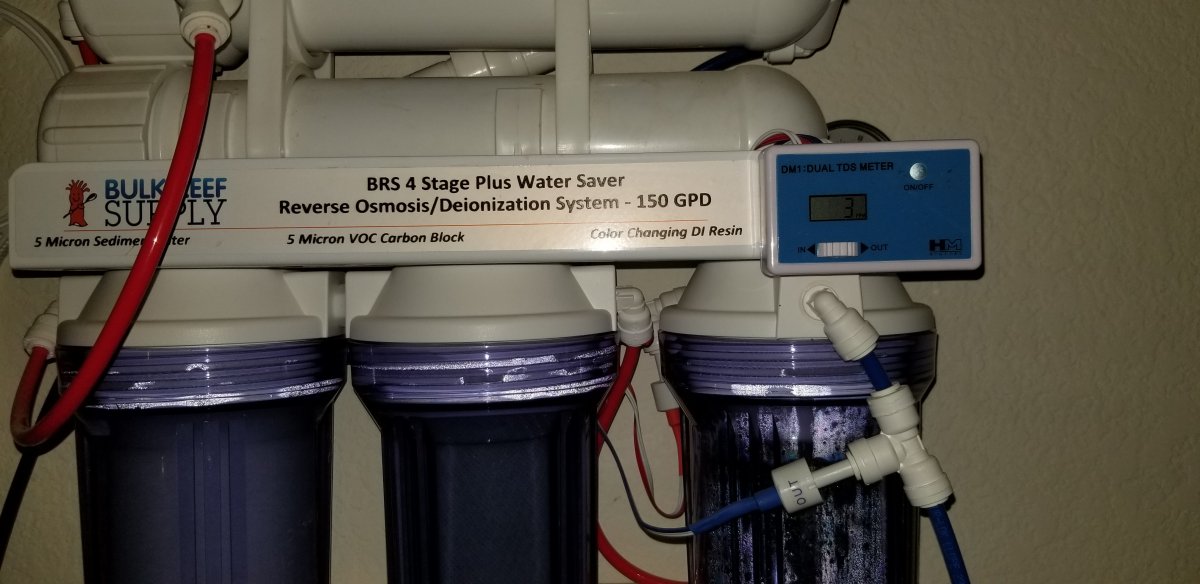

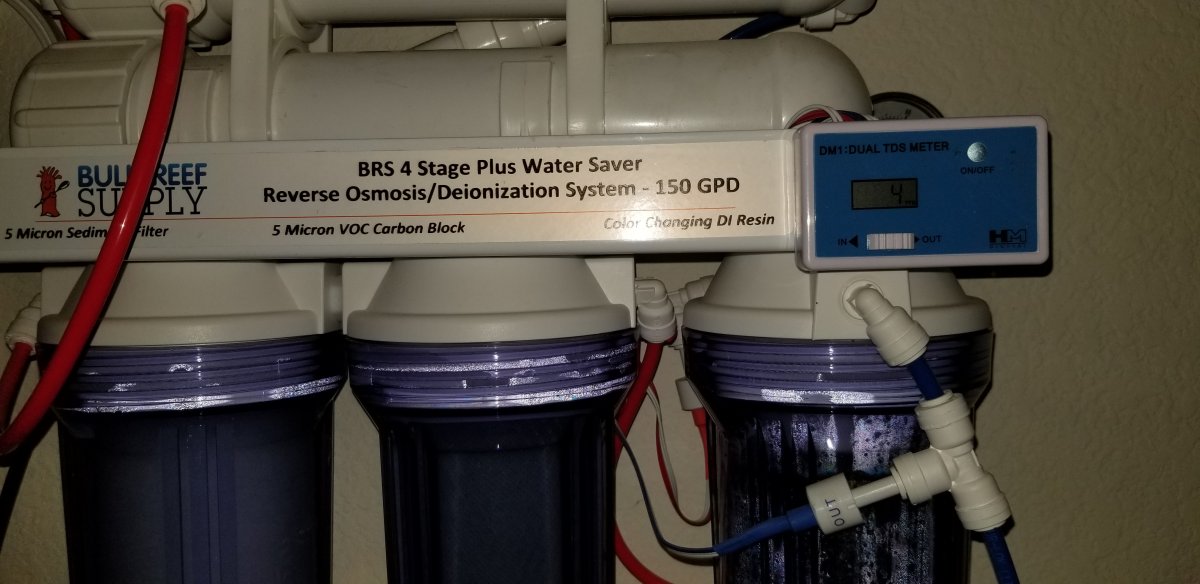

I ordered a filter replacement pack from BRS last week and replaced it this afternoon. After running about 50 gal of water I'm still measuring 3 TDS on the "In" and 4 TDS on the "Out". Higher output was something I've never seen before. What should I consider next? Run more water through and cross my fingers? Readjust the filters where they screw in? I can't see anything wrong with how they are screwed in now. Also, I made sure to pack the resin tight and flushed the membrane for a good 5 - 10 min.

Input pressure to the unit is 66psi.

What I thought to be a simple maintenance seems to have become more complicated. I have a 4-stage BRS RODI filter system that has been running well for about a year. In the last few weeks its been producing 2 TDS water and I could tell the resin was on the way out.

I ordered a filter replacement pack from BRS last week and replaced it this afternoon. After running about 50 gal of water I'm still measuring 3 TDS on the "In" and 4 TDS on the "Out". Higher output was something I've never seen before. What should I consider next? Run more water through and cross my fingers? Readjust the filters where they screw in? I can't see anything wrong with how they are screwed in now. Also, I made sure to pack the resin tight and flushed the membrane for a good 5 - 10 min.

Input pressure to the unit is 66psi.

Last edited: