- Joined

- Jun 5, 2019

- Messages

- 446

- Reaction score

- 324

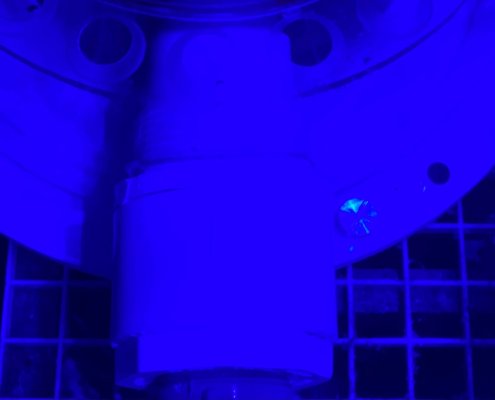

Trying to get some more pics going on here for all of you. My current oldest fish: some wild SI perculas.

This pair would be 10+ years old. Give me wild caught clowns every time over captive bred. Sure they often have brook, but it’s not too hard to treat these days. Oddly enough, they actually prefer the mag but since the move they haven’t left the gig. They do rotate back and forth though out the day. An interesting note - when they are only in the gig they become much darker - almost all black except for fins. Something to keep an eye on if they stay in the gig for a few weeks.

This pair would be 10+ years old. Give me wild caught clowns every time over captive bred. Sure they often have brook, but it’s not too hard to treat these days. Oddly enough, they actually prefer the mag but since the move they haven’t left the gig. They do rotate back and forth though out the day. An interesting note - when they are only in the gig they become much darker - almost all black except for fins. Something to keep an eye on if they stay in the gig for a few weeks.

Last edited: