Hello there,

I am in desperate need of help. After months of research I have finally purchased enough acrylic to build two tanks. One will be about 20 gallons (as a practice tank) and one will be 150 gallons.

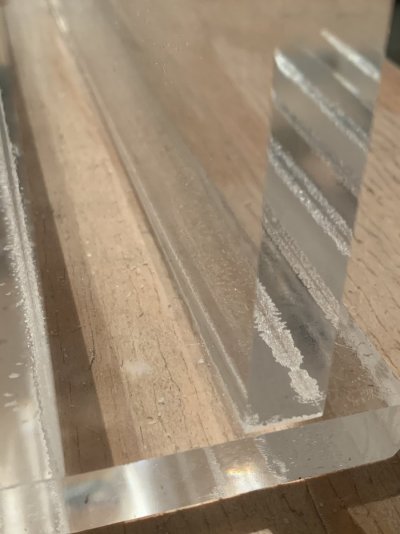

Before I touched any of that material I bought a 1 square foot x 1/2” thick cast acrylic sample which I cut into 4 pieces. I did this to test my seams, as well as edge cleaning. I have bonded two seams, one with a cut and scraped edge, and another with the factory polished edge. I used the pin method on one, with very thin wire.

About 20 seconds after applying Weld-on 4 I pulled the pins and everything looked 100% perfect. No bubbles or missing solvent anywhere. I could not find a single flaw.

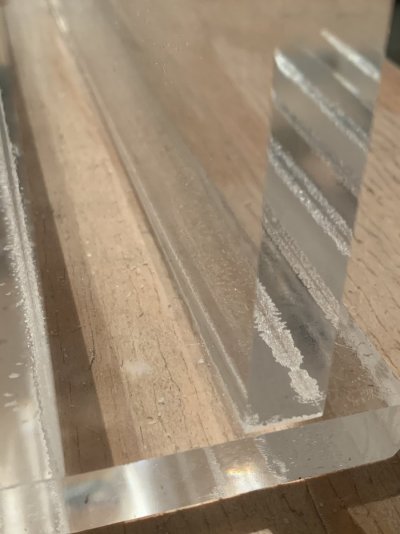

I went upstairs then came back down about an hour later. Nothing had been moved or messed with at all. What I found looks like air has somehow crept in along both sides of the seam. Please see the attached pictures. I can not have seams look like this as it will drive me crazy and I will not be confident with the durability of the tank. I am looking for any and all feedback as to why this may be happening.

Thank you for taking the time to read.

Best,

Chris

I am in desperate need of help. After months of research I have finally purchased enough acrylic to build two tanks. One will be about 20 gallons (as a practice tank) and one will be 150 gallons.

Before I touched any of that material I bought a 1 square foot x 1/2” thick cast acrylic sample which I cut into 4 pieces. I did this to test my seams, as well as edge cleaning. I have bonded two seams, one with a cut and scraped edge, and another with the factory polished edge. I used the pin method on one, with very thin wire.

About 20 seconds after applying Weld-on 4 I pulled the pins and everything looked 100% perfect. No bubbles or missing solvent anywhere. I could not find a single flaw.

I went upstairs then came back down about an hour later. Nothing had been moved or messed with at all. What I found looks like air has somehow crept in along both sides of the seam. Please see the attached pictures. I can not have seams look like this as it will drive me crazy and I will not be confident with the durability of the tank. I am looking for any and all feedback as to why this may be happening.

Thank you for taking the time to read.

Best,

Chris