Not yet. I would love to play with them, you have a link for the specific sensor ? Preferably from amazon

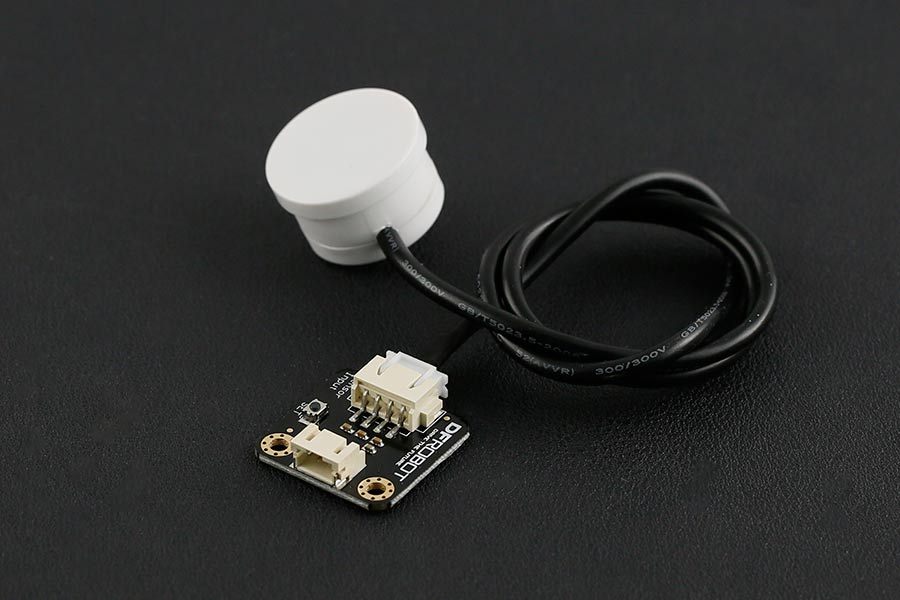

This is what I have from DFROBOT:

Gravity: Non-contact Digital Liquid Level Sensor for Arduino

This is a 5-24V XKC-Y25-T12V level sensor for Arduino with four levels of sensitivity . It use utilizes advanced signal processing technology with high-speed operation capacity to achieve non-contact liquid level detection. Suitable for water tank etc,.

They have similar on amazon:

Definetly not as cheap as float sensors, but I suppose it's hard to beat those as pretty much $2 a pop.

PS. One from DFROBOT comes with a breakout board that has a push-button sensitivity adjustment (3 levels).