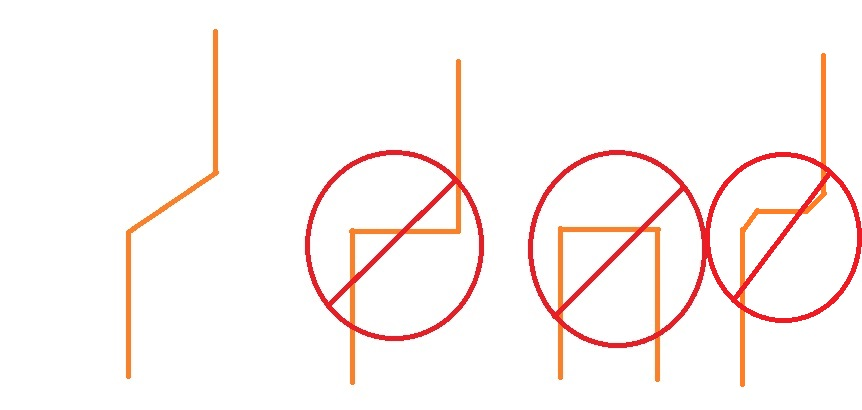

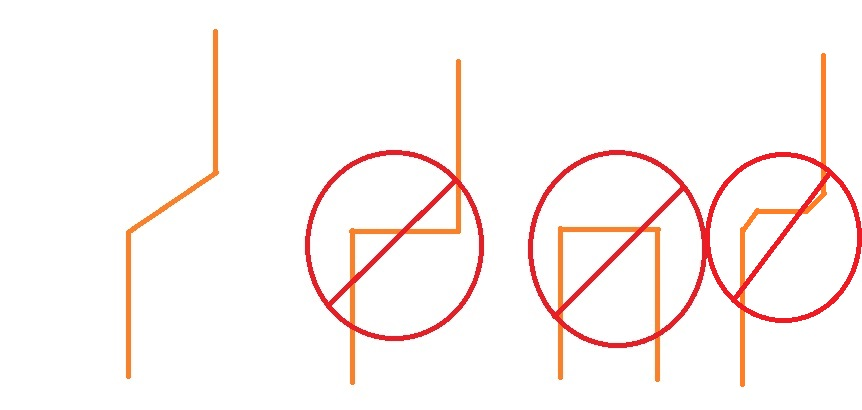

If I remember correctly there was basically no difference in using two 45's or one 90 degree elbow.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rev's 400+ Gallon Basement Inwall

- Monster Build

- Thread starter revhtree

- Start date

- Tagged users None

hybridazn

Acro killer.....

View BadgesSuper Moderator

Excellence Award

Reef Tank 365

Photo of the Month

3RMAS Member

Showcase Editor

Moderator Emeritus

My Aquarium Showcase

If I remember correctly there was basically no difference in using two 45's or one 90 degree elbow.

Yea, it was something minimal like less than 20gph difference

I remember that for two 45's that make a 90 degree turn but I'm talking about it never making a 90 at all.

Daniel@R2R

Living the Reef Life

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Photo of the Month

Article Contributor

Hospitality Award

Article Administrator

Reef Pumpkin Carver

R2R Secret Santa 2023

My Tank Thread

I promise you guys if we all start posting LSU pics in here, we'll get an update...or something...

;Troll

;Troll

Two 45's regardless if they are next to each other or a distance apart are going to act the same. Its the turn in the pipe that causes the head loss so no matter where it is located it will reduce flow "X" amount.I remember that for two 45's that make a 90 degree turn but I'm talking about it never making a 90 at all.

One test showing the difference in flow rates for a given scenario is not definitive.

Flow dynamics are more complicated than that. For instance, if this is return plumbing, you would have to test multiple flow rates on both extreme ends with multiple pipe diameters first, because you're undoubtedly going to get that dude that says his 1/2" plumbing is the same as 1.5" plumbing and thus it should only be a XX GPH or % flow reduction, when that's totally untrue.

The same pump on smaller diameter piping would have much higher frictional resistance, so if you had 1.5" piping and 1000 GPH at one valve setting (we'll call that setting #1),then cranked it to 1500 GPH (we'll call that setting #2) and noted those two set points on the pump, then took that same pump to a set of 1" piping that was configured identically and ran the same pump at the same 2 setting points, you would find that the #2 setting was much less than 50% more flow (i.e. you might get 700 GPH on setting #1 but only 950 GPH on setting #2, a 35% increase in flow instead of 1050 which would be 50% more flow) and that is because of frictional losses with smaller piping and the relationship between the flow rate and the frictional coefficient.

Once you have a basis for the flow rate curves for a given configuration, then and only then would you be able to change the plumbing setup and run the same tests again and have a valid comparison. And that would only be valid for that setup, and not necessarily directly applicable to anyone else's setup.

I admittedly haven't seen the video though so maybe they do this. I just wanted to strut my feathers around about my knowledge of flow dynamics, seeing as I cracked a mechanical engineering guidebook about it a few years ago to calculate weir flow rates for notched vs flat, and that now makes me an expert so there. I also like saying "flow dynamics"

Flow dynamics are more complicated than that. For instance, if this is return plumbing, you would have to test multiple flow rates on both extreme ends with multiple pipe diameters first, because you're undoubtedly going to get that dude that says his 1/2" plumbing is the same as 1.5" plumbing and thus it should only be a XX GPH or % flow reduction, when that's totally untrue.

The same pump on smaller diameter piping would have much higher frictional resistance, so if you had 1.5" piping and 1000 GPH at one valve setting (we'll call that setting #1),then cranked it to 1500 GPH (we'll call that setting #2) and noted those two set points on the pump, then took that same pump to a set of 1" piping that was configured identically and ran the same pump at the same 2 setting points, you would find that the #2 setting was much less than 50% more flow (i.e. you might get 700 GPH on setting #1 but only 950 GPH on setting #2, a 35% increase in flow instead of 1050 which would be 50% more flow) and that is because of frictional losses with smaller piping and the relationship between the flow rate and the frictional coefficient.

Once you have a basis for the flow rate curves for a given configuration, then and only then would you be able to change the plumbing setup and run the same tests again and have a valid comparison. And that would only be valid for that setup, and not necessarily directly applicable to anyone else's setup.

I admittedly haven't seen the video though so maybe they do this. I just wanted to strut my feathers around about my knowledge of flow dynamics, seeing as I cracked a mechanical engineering guidebook about it a few years ago to calculate weir flow rates for notched vs flat, and that now makes me an expert so there. I also like saying "flow dynamics"

Brew12

Electrical Gru

View BadgesExcellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

North Alabama Reef Club

Article Administrator

My Tank Thread

They didn't go into much detail. It is one of the few videos they have done that I though needed a lot of improvement. It was interesting, but far from conclusive.One test showing the difference in flow rates for a given scenario is not definitive.

Flow dynamics are more complicated than that. For instance, if this is return plumbing, you would have to test multiple flow rates on both extreme ends with multiple pipe diameters first, because you're undoubtedly going to get that dude that says his 1/2" plumbing is the same as 1.5" plumbing and thus it should only be a XX GPH or % flow reduction, when that's totally untrue.

The same pump on smaller diameter piping would have much higher frictional resistance, so if you had 1.5" piping and 1000 GPH at one valve setting (we'll call that setting #1),then cranked it to 1500 GPH (we'll call that setting #2) and noted those two set points on the pump, then took that same pump to a set of 1" piping that was configured identically and ran the same pump at the same 2 setting points, you would find that the #2 setting was much less than 50% more flow (i.e. you might get 700 GPH on setting #1 but only 950 GPH on setting #2, a 35% increase in flow instead of 1050 which would be 50% more flow) and that is because of frictional losses with smaller piping and the relationship between the flow rate and the frictional coefficient.

Once you have a basis for the flow rate curves for a given configuration, then and only then would you be able to change the plumbing setup and run the same tests again and have a valid comparison. And that would only be valid for that setup, and not necessarily directly applicable to anyone else's setup.

I admittedly haven't seen the video though so maybe they do this. I just wanted to strut my feathers around about my knowledge of flow dynamics, seeing as I cracked a mechanical engineering guidebook about it a few years ago to calculate weir flow rates for notched vs flat, and that now makes me an expert so there. I also like saying "flow dynamics"

I promise you guys if we all start posting LSU pics in here, we'll get an update...or something...

;Troll

Don't threaten me with a good time!

Daniel@R2R

Living the Reef Life

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Photo of the Month

Article Contributor

Hospitality Award

Article Administrator

Reef Pumpkin Carver

R2R Secret Santa 2023

My Tank Thread

I hear David is also a fan of the New Orleans Saints. Right, @revhtree? Maybe a flood of pics for LSU and NO will make him pay attention to his build thread.

Just so we are all talking the same thing on Rev's thread. lol

- Joined

- Jul 28, 2015

- Messages

- 4,668

- Reaction score

- 3,191

Yep, and the head pressure curve a pump can handle can make a big difference even between pumps with the same flow rate.They didn't go into much detail. It is one of the few videos they have done that I though needed a lot of improvement. It was interesting, but far from conclusive.

- Joined

- Aug 21, 2016

- Messages

- 5

- Reaction score

- 2

Well I just spent three days going through this thread. I am glad I stumbled upon it. I certainly took a lot of notes and enjoyed the fun and games along the way. The TANK, SUMP, and overall FISHROOM look amazing. Can't wait to see the updated FTS.

Daniel@R2R

Living the Reef Life

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Photo of the Month

Article Contributor

Hospitality Award

Article Administrator

Reef Pumpkin Carver

R2R Secret Santa 2023

My Tank Thread

I feel this is appropriate to post again...

- Joined

- Apr 26, 2016

- Messages

- 1,156

- Reaction score

- 1,598

Sweet the thread actually has a picture!Just so we are all talking the same thing on Rev's thread. lol

- Joined

- Apr 26, 2016

- Messages

- 1,156

- Reaction score

- 1,598

It might be that he's keeping supermodels instead of fish.I feel this is appropriate to post again...

@paulb are any of yours missing?

- Joined

- Jul 28, 2015

- Messages

- 4,668

- Reaction score

- 3,191

Following

hybridazn

Acro killer.....

View BadgesSuper Moderator

Excellence Award

Reef Tank 365

Photo of the Month

3RMAS Member

Showcase Editor

Moderator Emeritus

My Aquarium Showcase

So can we just move this thread to the lounge? It seems to have gone off the rails here....

Similar threads

- Replies

- 21

- Views

- 504

- Replies

- 18

- Views

- 256

- Replies

- 117

- Views

- 3,246

- Replies

- 1

- Views

- 64

New Posts

-

-

I'm preparing to set up a CO2 scrubber, and I have some questions...

- Latest: penguinexdeus

-