- Joined

- Apr 12, 2018

- Messages

- 86

- Reaction score

- 226

A few months ago I loaded my two cranky, over-tired (but mostly lovely) toddlers into the car, hoping they'd fall asleep on a drive around town... Somehow I ended up at a guy's house who was selling an aquarium (sorry sweetheart!)

A few hours later, I showed up at home with a new aquarium and no one napping.

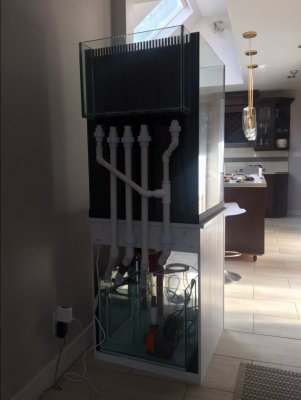

It was a custom built 80 gallon, 24" x 24"x 32" tank... I'd always had a thing for column tanks and I fell in love with this one instantly. Bevelled rimless starfire glass, black silicone, external overflow box with four 1" drains & two 3/4" returns plus a custom-made all-glass sump. The thing'd never even seen water.

It's been a few months since, and I've been snatching up second-hand equipment, painting stands, doing research and exploring the plumbing department at Home Depot. I wanted somewhere where I could document & track my progress and after being personally inspired by countless R2R Build Threads, I thought I may as well do so publicly... at the very least, you guys might keep me accountable and help me avoid cutting corners.

Here we gooooooooooo.....

KJ

A few hours later, I showed up at home with a new aquarium and no one napping.

It was a custom built 80 gallon, 24" x 24"x 32" tank... I'd always had a thing for column tanks and I fell in love with this one instantly. Bevelled rimless starfire glass, black silicone, external overflow box with four 1" drains & two 3/4" returns plus a custom-made all-glass sump. The thing'd never even seen water.

It's been a few months since, and I've been snatching up second-hand equipment, painting stands, doing research and exploring the plumbing department at Home Depot. I wanted somewhere where I could document & track my progress and after being personally inspired by countless R2R Build Threads, I thought I may as well do so publicly... at the very least, you guys might keep me accountable and help me avoid cutting corners.

Here we gooooooooooo.....

KJ