Projects with Sam

5000 Club Member

View BadgesPartner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

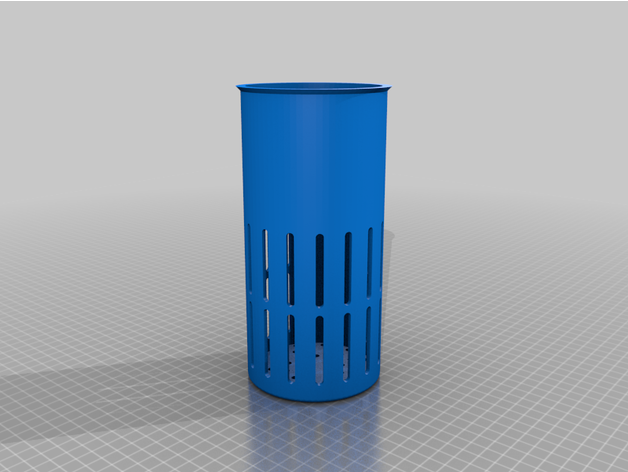

that's a clever design. no support needed to print itI have an old pillow and this

4" filter cup by diverkev

The files are for a 4" filter cup to replace filter socks in a sump. I used PETG for the print as it does not degrade in salt water.www.thingiverse.com

it seems like a lot of waste though.