- Joined

- Mar 12, 2018

- Messages

- 71

- Reaction score

- 28

Nice, thanks

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

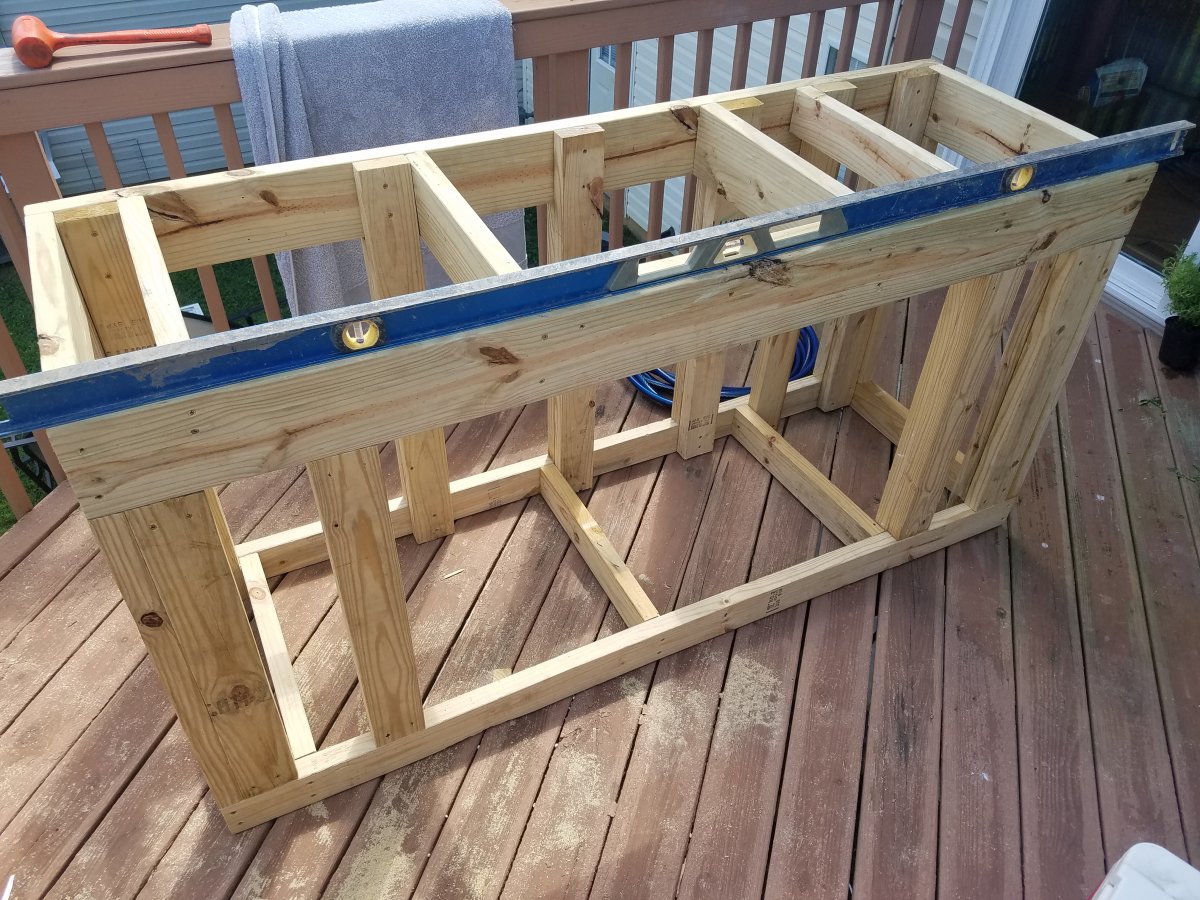

Heres a stand i made a while back for a 225, same footprint as your 180. I was going to add more framing but ran out of lumber and decided it was more than capable already.

One thing I'll make a note of when youre building your stand: periodically check to make sure your stand is level throughout your build. You dont want tk be screwing around with shims and wedges after youve got your tank on the stand.

Agree, level, and equally important checking for square constantly by diagonal measurements from corner to corner as you build.

I glue everything, and I pin nail together, and then check diagonal measurements before screwing solid while glue is still wet, building in shade helps give more time for that as well.

One more question, since my tank is rimless, how should the lip around the top be? Part of the 2x6 raised up a certain amount? Or is that not necessary?

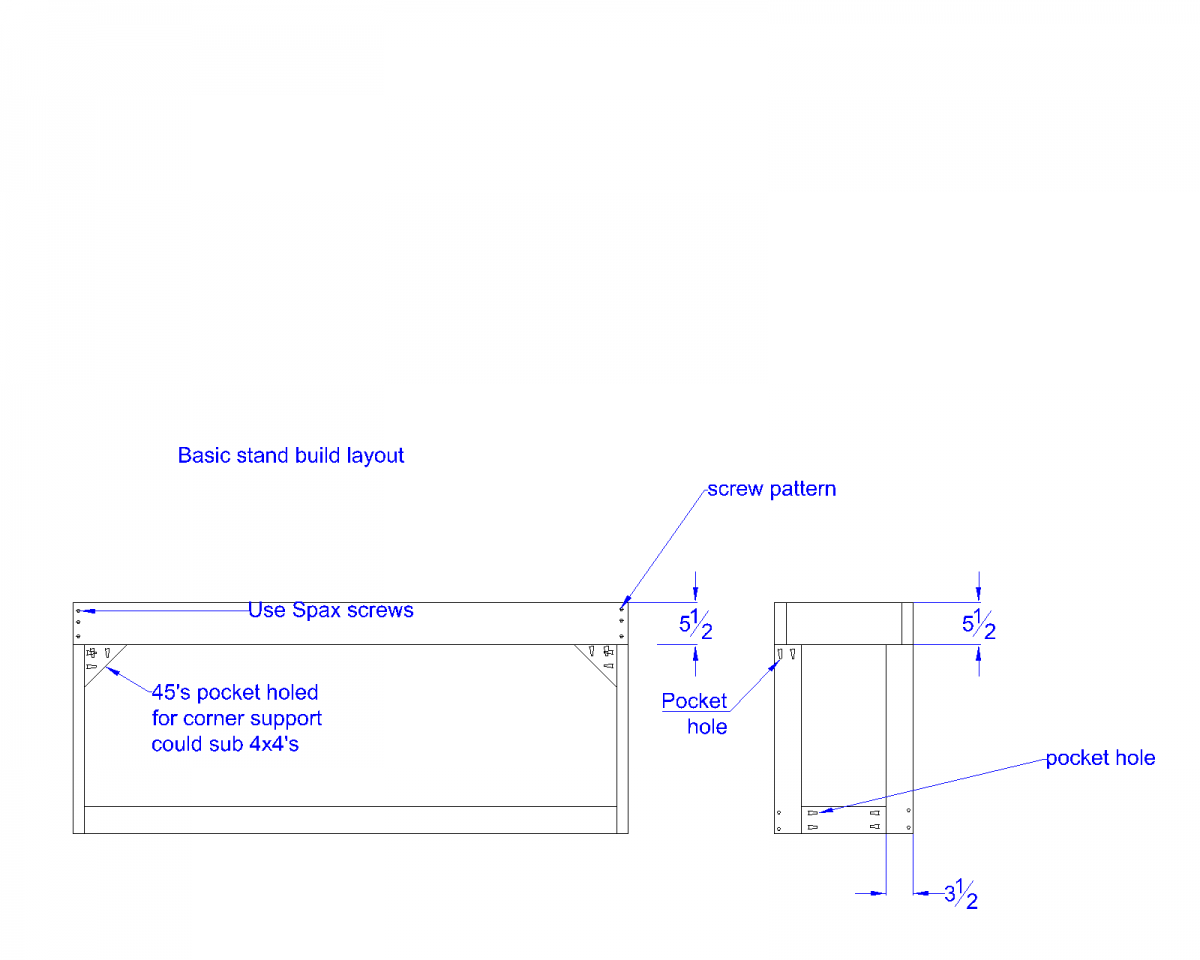

You have some pretty good advice here, I would suggest a do over. The structure of the supports and not constructed right. Here is what I suggest

I can't tell from the photos exactly what I'm looking at - is there a vertical 2x4 missing from the back in the first pic? In terms of compressive strength the vertical 2x4s are actually plenty strong and there aren't any long unsupported spans to sag in the middle. But as others have mentioned, racking is the worry. A sheet of 1/2" plywood across the back would fix that.

Still not the way I'd want to build it though!