Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing thread

- Thread starter PurpleMonster

- Start date

- Tagged users None

- Joined

- Sep 23, 2019

- Messages

- 624

- Reaction score

- 674

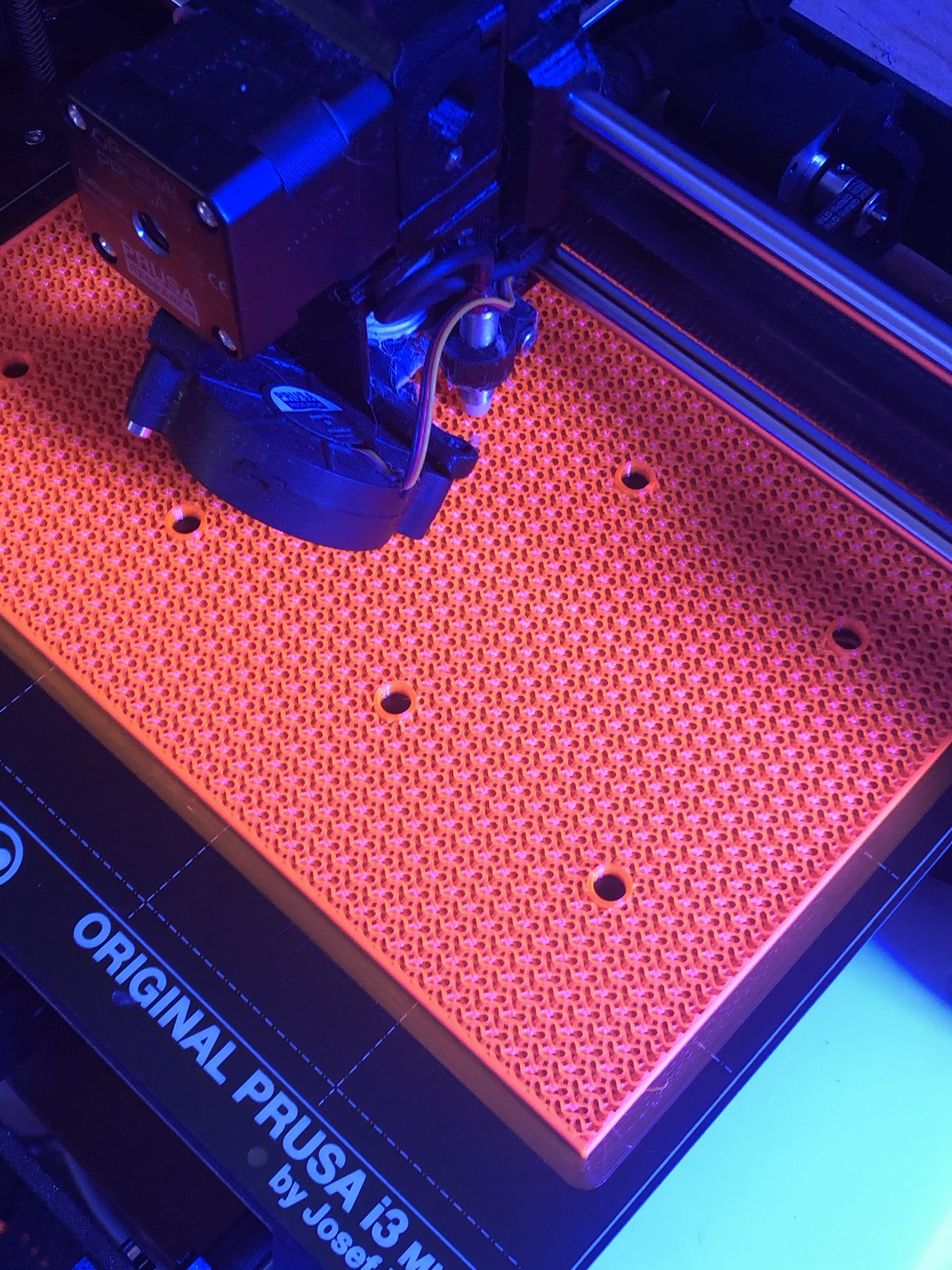

Thats going to take a while...

- Joined

- Oct 3, 2015

- Messages

- 5,145

- Reaction score

- 8,758

Thats going to take a while...

nah already finished. Was a custom skimmer stand for someone

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

Mine are definatly not as strong as injection molded plastic. Especially items with right angles like my probe holder which just broke when I removed it. I did not design it and think it should have had more infill in the corners after looking at the broken part. The directionparts are printed seams to make a big difference as well.

I also would say that 99% of my prints are not as strong as injection moulded parts of the same dimensions. However, most of my prints are pretty close and are more than strong enough.

If you want to increase strength you need to do 2 things.

1) fine tune the temp you are printing at and the amount you cool the print to ensure that the plastic going down and the plastic from the layer before are both soft enough to bond strongly while still being cooled quickly enough to maintain good quality.

2) Increasing infill does not increase print strength. This is a massive thing that I see a lot of people recommend. Infill over 25% if useless for strength IMO and really over 15% is not needed. If you want to increase strength increase the wall thickness. Increase the top and bottom layer thickness. As long as you are getting good layer adhesion then THIS is what will really increase your overall print strength.

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

Great thread!

I’m considering a 3D printer, don’t think I need anything too sophisticated. Brackets, test kit holders, whatever widgets kids come up with - I’m not sure what else I’d make with it.

What’s a good budget to start with for a beginner and recommendations on brands/models? Reviews online are kind of all over the place...

If you are on a budget and don't mind a bit of DIY then the Creality Ender 3 is a good but affordable entry level printer - some assembly is required (like a lego kit) and it may take a little bit of practice and reading to get it tuned in and printing really well. It's not hard but can be a little time consuming as you just need to "print, adjust and repeat".

But watch some youtube videos and spend some time learning what all the different slicer settings do and you will be able to pick it up in no time. And the knowledge you gain while doing so will be invaluable for when small things go wrong that most people who buy pre-built machines won't understand.

But if you don't want to spend any time or effort learning how printers work and how to dial the settings in and fix them then you need to spend money instead and get a Prusa. They usually work very well more or less straight out of the box, they are generally very reliable and they also have customer service if you can't get it going, but you will pay a lot more for it.

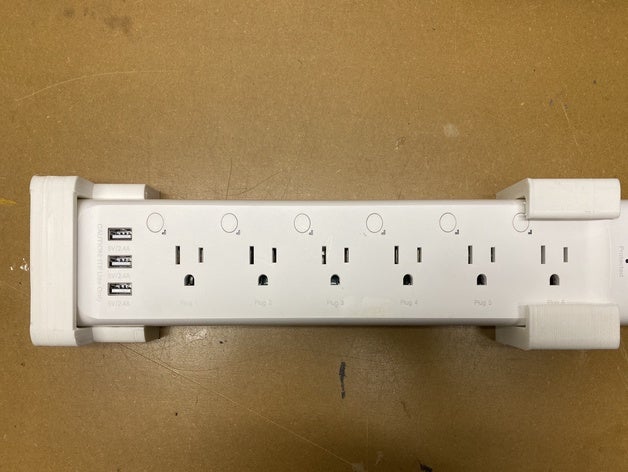

Designed this bracket for kasa smart powerstrip (hs300). https://www.thingiverse.com/thing:3898028

Its pretty basic, holds the powerstrip against wall, theres two holes for each bracket to screw in. The initial version was mostly composed of square/rectangular shaped combined with various boolean operators (in blender). I have iterated over the design to add bevels in edges where it makes sense.

Printed in ender 3, with 0.8mm nozzle at 60mm speed. Print time was little less than two hours if i recall correctly. Theres noticeable under extrusion. But its still functional and good enough for my garage tank

with the powerstrip

These are pretty handy powerstrip, with surge protection, on board switches for each outlet, wifi controllable and current monitoring on each outlet. Each outlet can also be assigned digital timers .

.

I went through bed level and calibration chores after the print. I'll see how it changes the print quality. Speed is actually turning out my biggest factor for print quality. Anything printed at 20mm is pretty good quality. Things starts looking bad after 60-65.

Its pretty basic, holds the powerstrip against wall, theres two holes for each bracket to screw in. The initial version was mostly composed of square/rectangular shaped combined with various boolean operators (in blender). I have iterated over the design to add bevels in edges where it makes sense.

Printed in ender 3, with 0.8mm nozzle at 60mm speed. Print time was little less than two hours if i recall correctly. Theres noticeable under extrusion. But its still functional and good enough for my garage tank

with the powerstrip

These are pretty handy powerstrip, with surge protection, on board switches for each outlet, wifi controllable and current monitoring on each outlet. Each outlet can also be assigned digital timers

I went through bed level and calibration chores after the print. I'll see how it changes the print quality. Speed is actually turning out my biggest factor for print quality. Anything printed at 20mm is pretty good quality. Things starts looking bad after 60-65.

Thanks that is helpful. I will have to see if I can increase the wall thickness at the 2 corners.I also would say that 99% of my prints are not as strong as injection moulded parts of the same dimensions. However, most of my prints are pretty close and are more than strong enough.

If you want to increase strength you need to do 2 things.

1) fine tune the temp you are printing at and the amount you cool the print to ensure that the plastic going down and the plastic from the layer before are both soft enough to bond strongly while still being cooled quickly enough to maintain good quality.

2) Increasing infill does not increase print strength. This is a massive thing that I see a lot of people recommend. Infill over 25% if useless for strength IMO and really over 15% is not needed. If you want to increase strength increase the wall thickness. Increase the top and bottom layer thickness. As long as you are getting good layer adhesion then THIS is what will really increase your overall print strength.

- Joined

- Jan 5, 2016

- Messages

- 697

- Reaction score

- 1,232

No worries, I would just increase the wall thickness overall though (I don't think you can do it in certain sports anyway but that might just be my slicer).Thanks that is helpful. I will have to see if I can increase the wall thickness at the 2 corners.

I use 6-8 walls + 20% infill for structural parts that will be under a dynamic load (such as parts for a new 3D printer) and 4-6 walls + 20% infill for static parts that I still want to be decently strong (such as a float switch holder or a feeding ring) and 1-3 walls + 15% infill for draft/test prints or parts that really don't need to be that strong.

As long as your prints aren't breaking at the layer lines that should help the strength a lot. If your parts are breaking at the layer lines then it is an adhesion (temp and/or cooling) issue.

Been out for a while but figured you guys would appreciate something else printing has enabled.

Took a common skull model, cut out a spot for a frag plug and printed it. Made a silicone mold from the print then used that to make cement skulls (emarco-400). Glued down some GSP and forgot about it for a few months.

Took a common skull model, cut out a spot for a frag plug and printed it. Made a silicone mold from the print then used that to make cement skulls (emarco-400). Glued down some GSP and forgot about it for a few months.

Hilarious!

Been out for a while but figured you guys would appreciate something else printing has enabled.

Took a common skull model, cut out a spot for a frag plug and printed it. Made a silicone mold from the print then used that to make cement skulls (emarco-400). Glued down some GSP and forgot about it for a few months.

I love it, makes me think of

Very cool, looks great!! but still no GSP, Xenia or invasive Palys in my tank.

I have another one with Mystic sunset montipora.

Also have some naked ladies with cyphastrea and Monti on them.

Also have some naked ladies with cyphastrea and Monti on them.

Overture was the brand I used, until I started using 0.03 accuracy filament, now I'm trying to use up all my 0.05 stuff.

I just bought a 3d printer and am going to start learning CAD tonight (merry Christmas to myself) ... anyone have any tips or cool stuff they printed for their tank?

I'd like to build mounting arms for my prime's for my next rimless tank.

I'd like to build mounting arms for my prime's for my next rimless tank.

Similar threads

- Replies

- 2

- Views

- 82

- Replies

- 20

- Views

- 1,083