Test the magnets and make sure they are strong enough before putting epoxy over them. Use a 1/4 inch piece of wood and they should still hold together strongly. If they are a little week use more magnets spaced out.Would you say about 1/8' thick is enough? And I'm assuming you mean on both magnets, the one in the stand and the one on the front

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building stand front, need magnetic attachment device.

- Thread starter glb

- Start date

- Tagged users None

Would you say about 1/8' thick is enough? And I'm assuming you mean on both magnets, the one in the stand and the one on the front

mine are about a 1/16 recessed

For a neodymium magnet? What width? It’s always safest and easiest imo to just check the poundage rating. If there is one.Would you say about 1/8' thick is enough? And I'm assuming you mean on both magnets, the one in the stand and the one on the front

I think it’s 1.25”. It’s coming tomorrow.For a neodymium magnet? What width? It’s always safest and easiest imo to just check the poundage rating. If there is one.

I'm in a similar boat, but I'm building doors (panels) for the front of a 8020 stand. I have the magnets (neos) that I ordered from Amazon, what I don't have is what the magnets can mate with. I still want it to look good when I open the stand. I was thinking of just painting some small steel plates and counter-sink a nice looking screw in it using a T-slot nut on the other side. I've also thought of just doing that with the predrilled magnets, but wondering how long before they rusted, or if they did at all..... Would love to see if anyone has done this on 8020.

I think you can use magnet on both the stand and the front by turning one around.I'm in a similar boat, but I'm building doors (panels) for the front of a 8020 stand. I have the magnets (neos) that I ordered from Amazon, what I don't have is what the magnets can mate with. I still want it to look good when I open the stand. I was thinking of just painting some small steel plates and counter-sink a nice looking screw in it using a T-slot nut on the other side. I've also thought of just doing that with the predrilled magnets, but wondering how long before they rusted, or if they did at all..... Would love to see if anyone has done this on 8020.

You mean that industrial thin type? I love that stuff and use it everywhere in my system that’s above water. In my electrical cabinet I mount modules and lightweight monitors, etc. so I can move them around if I need to. I hadn’t thought about that for the stand front, but it’s an interesting idea. I’d have to nail it down to the stand and front for longevity. Thanks for the idea!I will admit I didn’t read much of the thread but have you thought about Velcro? I used magnets on my last cover and will go with Velcro this time. My cover is fairly light though.

You want stronger magnets than you typically get at the hardware store. I used Neodymium magnets from Amazon with a hole in the center to attach them. .

Weigh your frame and depending if it is supported on the bottom or not you may need more or stronger magnets. Use a router or a Forster bit if you want them flush with the back of your frame. You want to coat them if you are concerned about them getting wet, as they will corrode.

I bought these but I think they’re way too strong. I had difficulty pulling apart one of them from metal. I’m going to see about getting some smaller ones. I’m afraid that using that much force pulling the stand front off would eventually damage it. I’m going to weigh my stand front and then head over to Home Depot to find something less powerful. And yes I managed to pinch my finger between two of them. Ouch!!!!

I bought these but I think they’re way too strong. I had difficulty pulling apart one of them from metal. I’m going to see about getting some smaller ones. I’m afraid that using that much force pulling the stand front off would eventually damage it. I’m going to weigh my stand front and then head over to Home Depot to find something less powerful. And yes I managed to pinch my finger between two of them. Ouch!!!!

Inset them a little deeper so there is more gap

Can you point to where on Blum you are referring to? I only see hinges.Blum makes some fancy magnetic cabinet hardware but there are also plenty of other options available. Some require no handle as you can push them in and they pop out or a more simple mechanism.

- Joined

- Sep 16, 2018

- Messages

- 516

- Reaction score

- 922

Magnet to metal plate. Use smaller plate to reduce pull. Don’t go magnet to magnet.I bought these but I think they’re way too strong. I had difficulty pulling apart one of them from metal. I’m going to see about getting some smaller ones. I’m afraid that using that much force pulling the stand front off would eventually damage it. I’m going to weigh my stand front and then head over to Home Depot to find something less powerful. And yes I managed to pinch my finger between two of them. Ouch!!!!

Yes you’re absolutely right. I can’t separate the magnets from each other at all. I did put something metal up to it and it was still incredibly difficult to separate.Magnet to metal plate. Use smaller plate to reduce pull. Don’t go magnet to magnet.

That’s a good idea. My stand front is only 3/4” thick, so I’m thinking I need to put the magnet in the stand itself to create distance. Would a metal washer work for the stand front itself? I’d like to find something about the same size as the magnet because I need to buy a new drill bit to make the holes.Inset them a little deeper so there is more gap

- Joined

- Sep 16, 2018

- Messages

- 516

- Reaction score

- 922

i have a fender washer mounted to my panel that holds the doors and the magnet imbedded in the frame. The screw that holds the fender washer sticks out slightly above the washer. With a smaller flat top screw the magnet gets very close to the washer and the hold is strong. With a larger rounded head screw there is more distance and the hold is light. I played with different screws until I got the hold I wanted.That’s a good idea. My stand front is only 3/4” thick, so I’m thinking I need to put the magnet in the stand itself to create distance. Would a metal washer work for the stand front itself? I’d like to find something about the same size as the magnet because I need to buy a new drill bit to make the holes.

Thanks! How deep did you drill the holes for the washer and magnet?i have a fender washer mounted to my panel that holds the doors and the magnet imbedded in the frame. The screw that holds the fender washer sticks out slightly above the washer. With a smaller flat top screw the magnet gets very close to the washer and the hold is strong. With a larger rounded head screw there is more distance and the hold is light. I played with different screws until I got the hold I wanted.

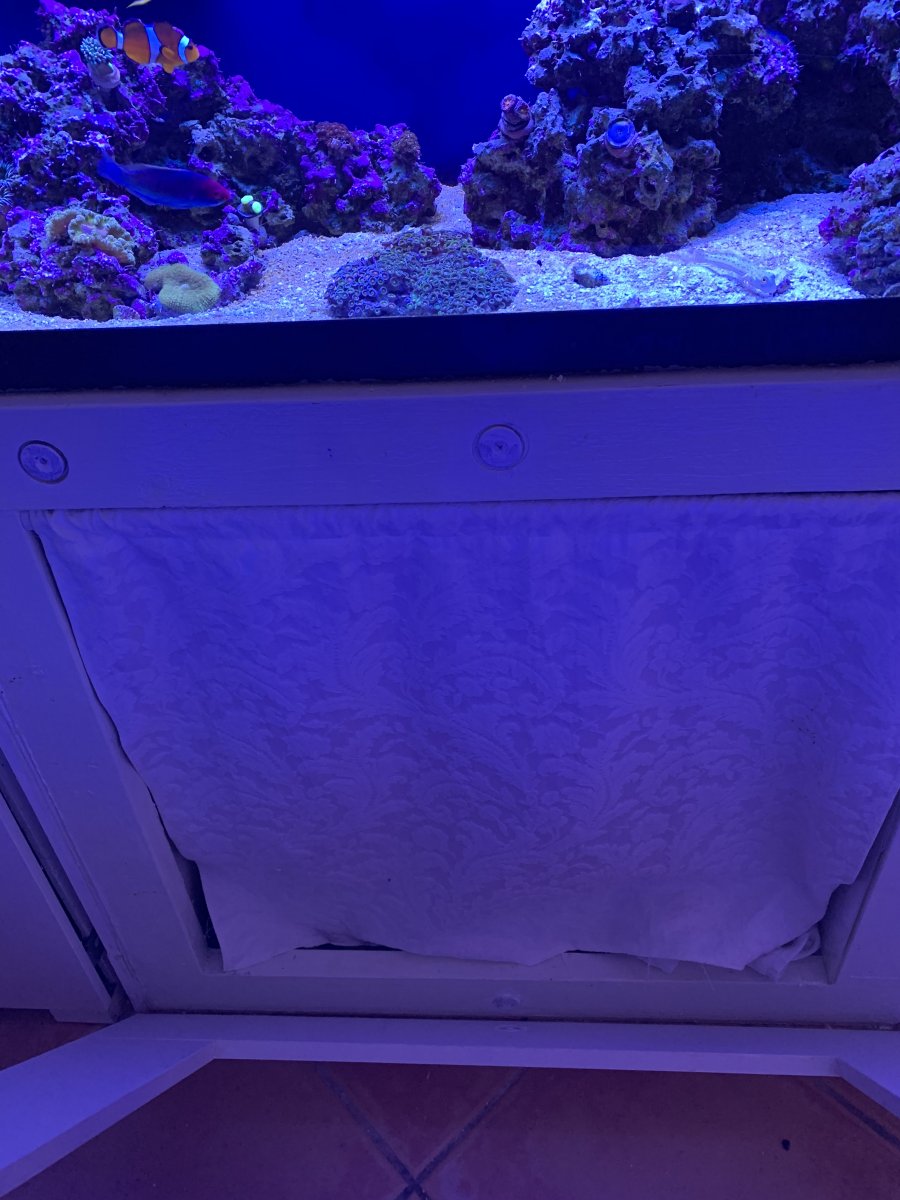

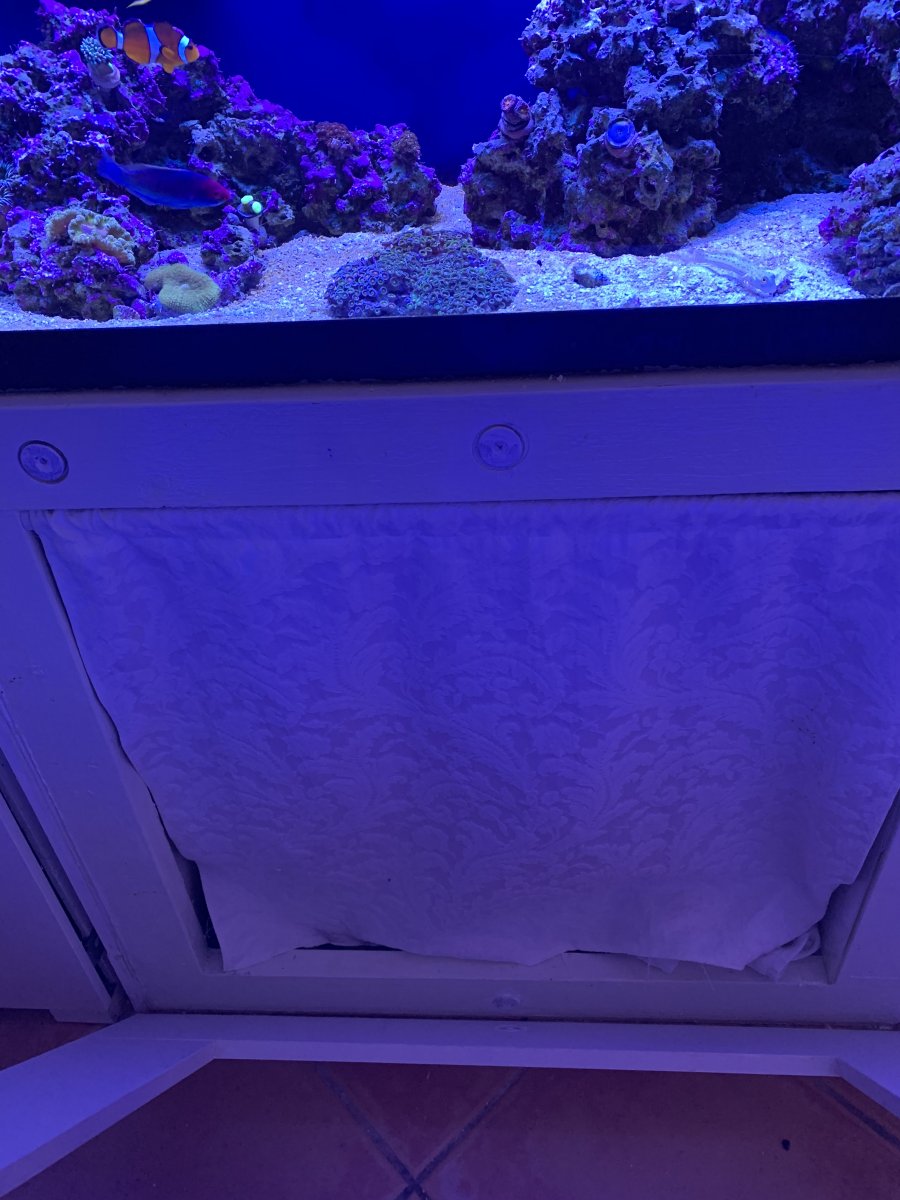

That’s beautiful

Here’s my finished product. I have a curtain in the gap until I build the doors. I still need to coat the magnets with more paint but they’re holding just right with fender stainless steel washers.

Similar threads

- Replies

- 5

- Views

- 116