Appreciate the info, definitely worth doing. I have a few running tanks so it is frustrating when it's replacement time. Those things add up at retail.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Filter Socks

- Thread starter 8pixel

- Start date

- Tagged users None

- Joined

- Jul 30, 2019

- Messages

- 3

- Reaction score

- 0

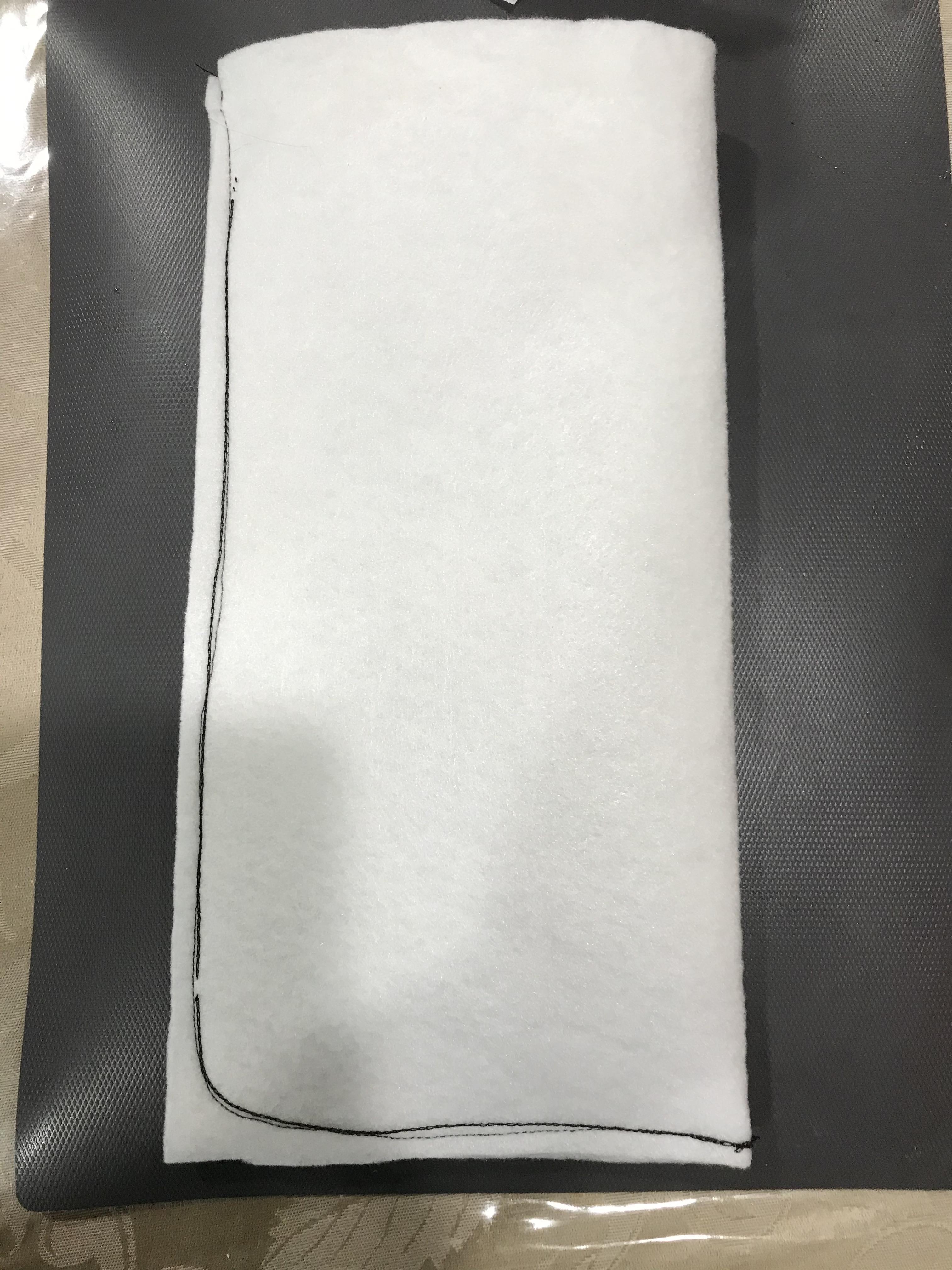

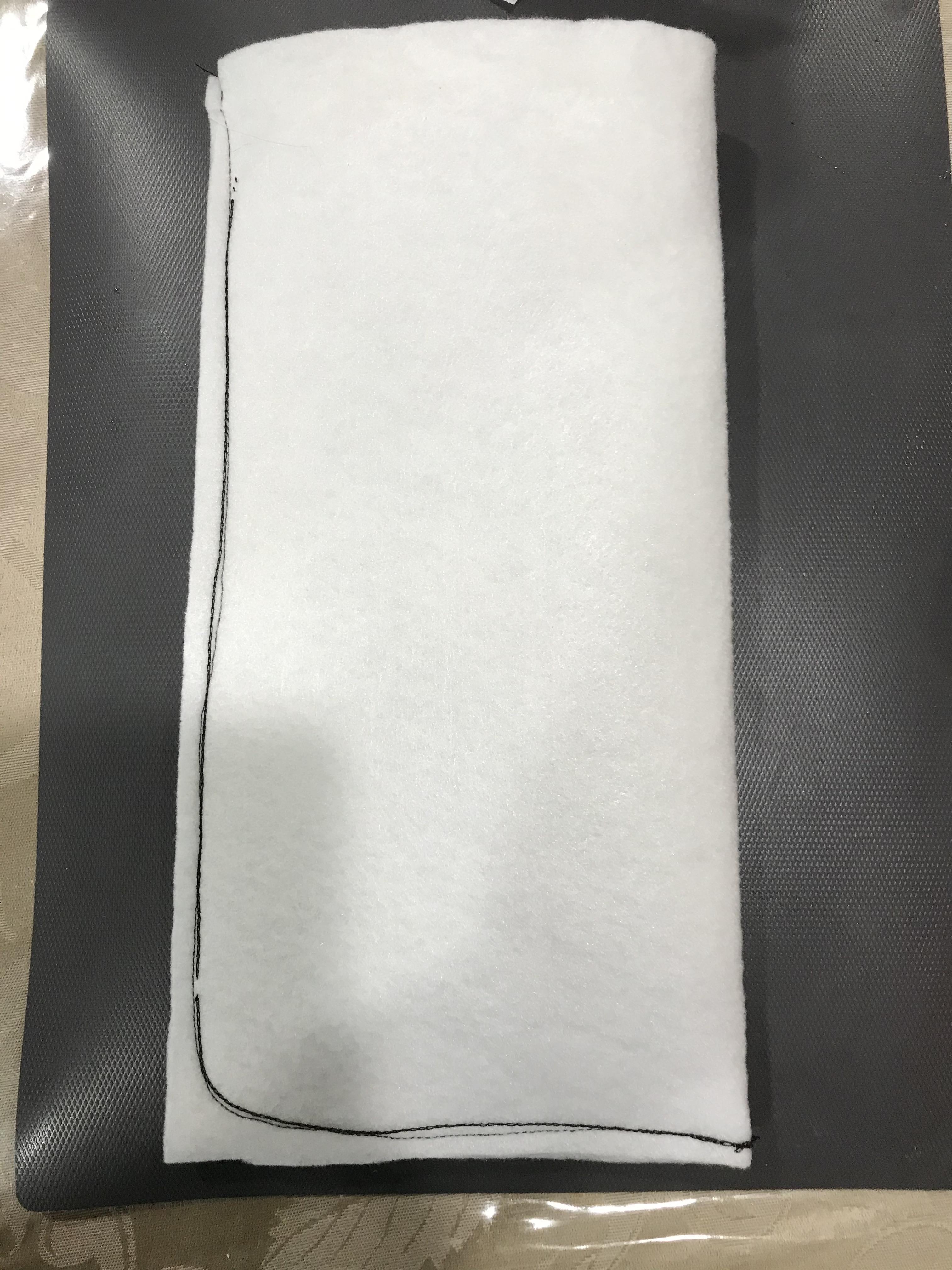

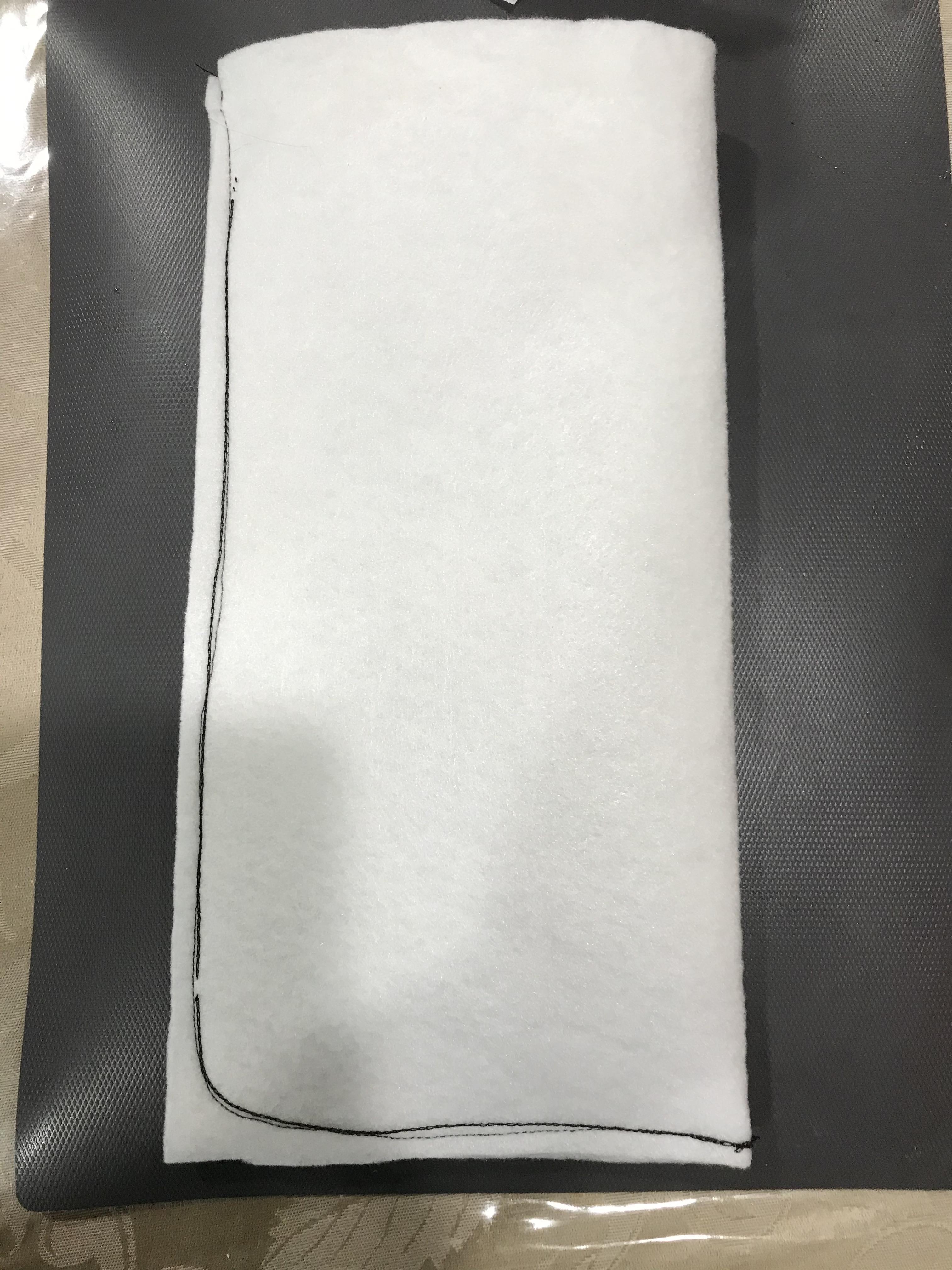

A few people have asked me how I make my filter socks so I figure I'd post a thread in case this can be helpful to others. All you need is a sewing machine, very basic sewing skills and about 30-45 minutes every 2 months. I buy my polyester felt from JoAnn Fabric for about $2.50/yard (usually $5 but they have online coupons every month or so for 50% off). One yard of material will give me 15 12" socks which comes out to around .16 cents a piece. Old ones just get tossed and no need for washing and drying, etc. Changing them out twice a week these will last you almost 2 months.

The key to making these easy to use and change is the ring which you only need to make once. When it comes time to change socks, you just pull out the ring and thread it in to the new sock through the upper slot and you are done….30 seconds tops.

Below are the steps with photos.

How great

It's very creative, congratulations.

I'm sure I'll use this idea, thank you.

Your ideas are like YouTube R&Z plumbing.

- Joined

- Feb 26, 2014

- Messages

- 467

- Reaction score

- 209

Very cool that’s for the write up

I’m not sure I can get that in Australia, all I can find is acrylic felt, is it the same stuff?

www.spotlightstores.com

www.spotlightstores.com

General Purpose Felt By The Metre | Spotlight Australia

At Spotlight, you can find general purpose felt by the metre in various grades, thickness and colours. Browse our entire collection of fabrics today!

Thank you Dan!I’m not sure I can get that in Australia, all I can find is acrylic felt, is it the same stuff?

General Purpose Felt By The Metre | Spotlight Australia

At Spotlight, you can find general purpose felt by the metre in various grades, thickness and colours. Browse our entire collection of fabrics today!www.spotlightstores.com

I've been searching for this for ages. In the USA they call this stuff Polyester. Over here they call it Acrylic. Spotlight has a tendency to not provide accurate specifications. For example, micron isn't specified. When I asked a Spotlight sales representative about micron size, she didn't even know what I was taking about and neither did her supervisor, so they said that they'd check with their supplier/manufacturer in China and get back to me - that never happened.

I suppose that I'll pretty much know how small the perforations are by how fast it clogs up. I currently alternate between 100μ and 200μ. The 100μ socks need changing every 3 to 4 days. The 200μ can go a week. Of course those figures are based on what I feed and how often.

It's not going to break my bank account to give this stuff a shot. I'm pretty good at sewing so that's a plus.

Cheers

Bill

Last edited:

- Joined

- May 14, 2020

- Messages

- 41

- Reaction score

- 138

This thread is amazing. I have a Waterbox AIO which uses 2.75" socks. These are very hard to find and very expensive. From Waterbox, one sock costs $9.99!!! I have found cheaper ones for $5 but they did not fit exactly right.

My wife just sewed me 48 of these. I found packs of 24 sheets of EcoFi felt for $9 on Amazon. The sheets are 9"x12" which is almost exactly the size I need.

My wife just sewed me 48 of these. I found packs of 24 sheets of EcoFi felt for $9 on Amazon. The sheets are 9"x12" which is almost exactly the size I need.

I've been doing this DIY sock about over 5 years now, and has over the years refined the sock so the cutting/sewing is absolutely down to a minimum, and the ring attachment is extremely easy and straightforward. I still use a brand new sock each time I change the sock and just toss out the used one.

This is for 4" sock (100mm for metric folks)

each yard of fabric is 72"x36". I cut them to 12"x12" square pieces. I don't even have to measure, just fold the 36" side into 3 equal parts and cut, then cut the 72" side to 6 equal parts. One yard yields 18 socks and enough to last me 3 months.

Then I sew by simply folding in half, and just saw the long side then the bottom then back to make a bag. That's it. (I am still using the handheld portable Singer sewing machine from when I posted years ago)

For the ring attachment, I use a 3D printed ring that I designed. Its extremely simple anyone can easily draw up the 3D file. The holes are not there for decoration. Its to minimize the filament used and reduce print time. Also when water level on sock starts to reach the top, water can still flow out the material through the holes. A put a lot of thought into this simple design.

Its basically two rings, and the sock goes between the two rings. Larger ring goes outside the sock, smaller ring goes inside the sock, then press down.

voila! DIY sock!

Print using PETG, as PLA softens in saltwater.

Hope this helps.

This is for 4" sock (100mm for metric folks)

each yard of fabric is 72"x36". I cut them to 12"x12" square pieces. I don't even have to measure, just fold the 36" side into 3 equal parts and cut, then cut the 72" side to 6 equal parts. One yard yields 18 socks and enough to last me 3 months.

Then I sew by simply folding in half, and just saw the long side then the bottom then back to make a bag. That's it. (I am still using the handheld portable Singer sewing machine from when I posted years ago)

For the ring attachment, I use a 3D printed ring that I designed. Its extremely simple anyone can easily draw up the 3D file. The holes are not there for decoration. Its to minimize the filament used and reduce print time. Also when water level on sock starts to reach the top, water can still flow out the material through the holes. A put a lot of thought into this simple design.

Its basically two rings, and the sock goes between the two rings. Larger ring goes outside the sock, smaller ring goes inside the sock, then press down.

voila! DIY sock!

Print using PETG, as PLA softens in saltwater.

Hope this helps.

If you have the ring uploaded somewhere I can add it to the 3d print archive thread! We have a very active community of 3d printer enthusiasts here.I've been doing this DIY sock about over 5 years now, and has over the years refined the sock so the cutting/sewing is absolutely down to a minimum, and the ring attachment is extremely easy and straightforward. I still use a brand new sock each time I change the sock and just toss out the used one.

This is for 4" sock (100mm for metric folks)

each yard of fabric is 72"x36". I cut them to 12"x12" square pieces. I don't even have to measure, just fold the 36" side into 3 equal parts and cut, then cut the 72" side to 6 equal parts. One yard yields 18 socks and enough to last me 3 months.

Then I sew by simply folding in half, and just saw the long side then the bottom then back to make a bag. That's it. (I am still using the handheld portable Singer sewing machine from when I posted years ago)

For the ring attachment, I use a 3D printed ring that I designed. Its extremely simple anyone can easily draw up the 3D file. The holes are not there for decoration. Its to minimize the filament used and reduce print time. Also when water level on sock starts to reach the top, water can still flow out the material through the holes. A put a lot of thought into this simple design.

Its basically two rings, and the sock goes between the two rings. Larger ring goes outside the sock, smaller ring goes inside the sock, then press down.

voila! DIY sock!

Print using PETG, as PLA softens in saltwater.

Hope this helps.

If you have the ring uploaded somewhere I can add it to the 3d print archive thread! We have a very active community of 3d printer enthusiasts here.

I just uploaded to Thingiverse.

Thanks Doughboy! This will be a great addition! I will include a link to your post for further instructions.I just uploaded to Thingiverse.

I think there is a post in this thread that some1 used a small hand held sewing machine that uses 2 AA batteries. I was on EBAY the other month and i got a small sewing machine (because I couldn't find mine) $50+ i thinkFor those of us without a sewing machine, is there a suitable glue that can be used to make these?

This is similar to the one that I have

- Joined

- Jul 1, 2015

- Messages

- 2,260

- Reaction score

- 1,063

Anyone get material recently from JoAnn? Is there a specific brand that has been reef safe?

Similar threads

- Replies

- 16

- Views

- 519

- Replies

- 13

- Views

- 163

- Replies

- 1

- Views

- 110

- Replies

- 6

- Views

- 182

- Price: $25

- Shipping Available

- Replies

- 4

- Views

- 174