- Joined

- Oct 29, 2017

- Messages

- 153

- Reaction score

- 79

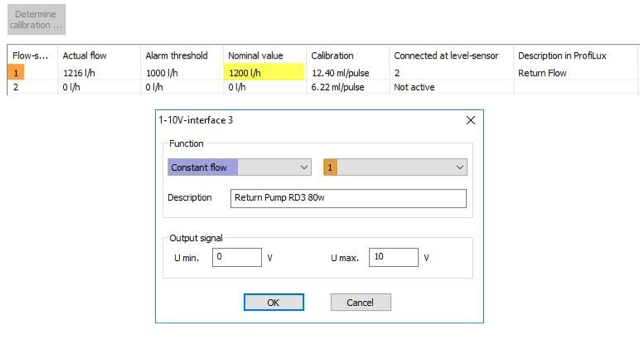

Thanks! That was actually my question [emoji1]... I have 25mm pipe. So which sensor will provide the min restriction? The 9000l/h or the 6000L/h?

Understand that Marco kind of stole my thunder with the announcement but could anyone let me know what is the correct (metric) flow sensor for 25mm pipe [emoji16]?

Heres a little more info about the GHL vortex flow sensors. Hope it helps.

Flow Sensor 2000 l/h - 10mm (3/8″ ID) (26gph – 528gph)

Flow Sensor 5000 l/h - 20mm (3/4″ ID) (79gph – 1,320gph)

Flow Sensor 9000 l/h - 25mm (1″ ID) (142gph – 2,377gph)