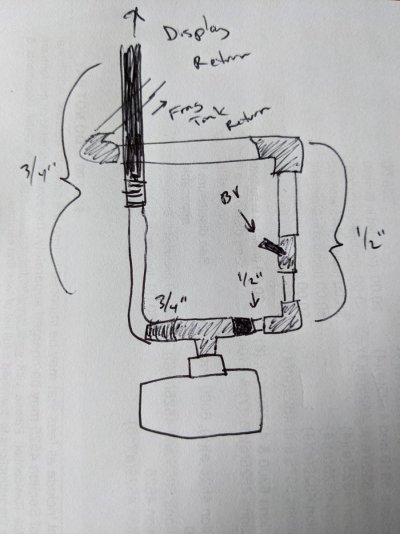

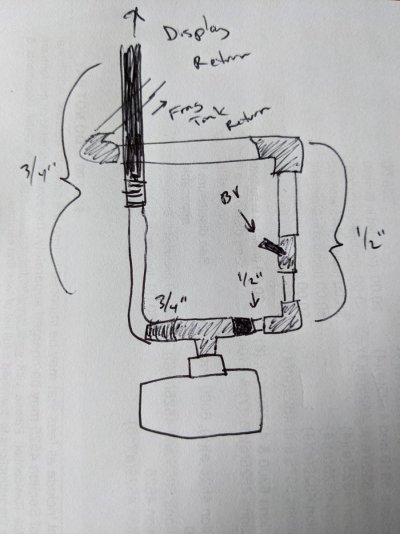

I originally posted in DIY, and I'm now trying to figure out plumbing sizing coming from a single return pump. I was going to T off from my return pump (COR-15) to fit 3/4" line to my display and 1/2" to my frag tank.

Is there any negligible difference if I T off with a 3/4" connector vs going 1" out of my return and reducing both connections? Also, should I have a gate valve to control flow to my display? I'm planning a gate valve on the frag tank drain to control the flow for that. Thanks.

Is there any negligible difference if I T off with a 3/4" connector vs going 1" out of my return and reducing both connections? Also, should I have a gate valve to control flow to my display? I'm planning a gate valve on the frag tank drain to control the flow for that. Thanks.

Last edited: