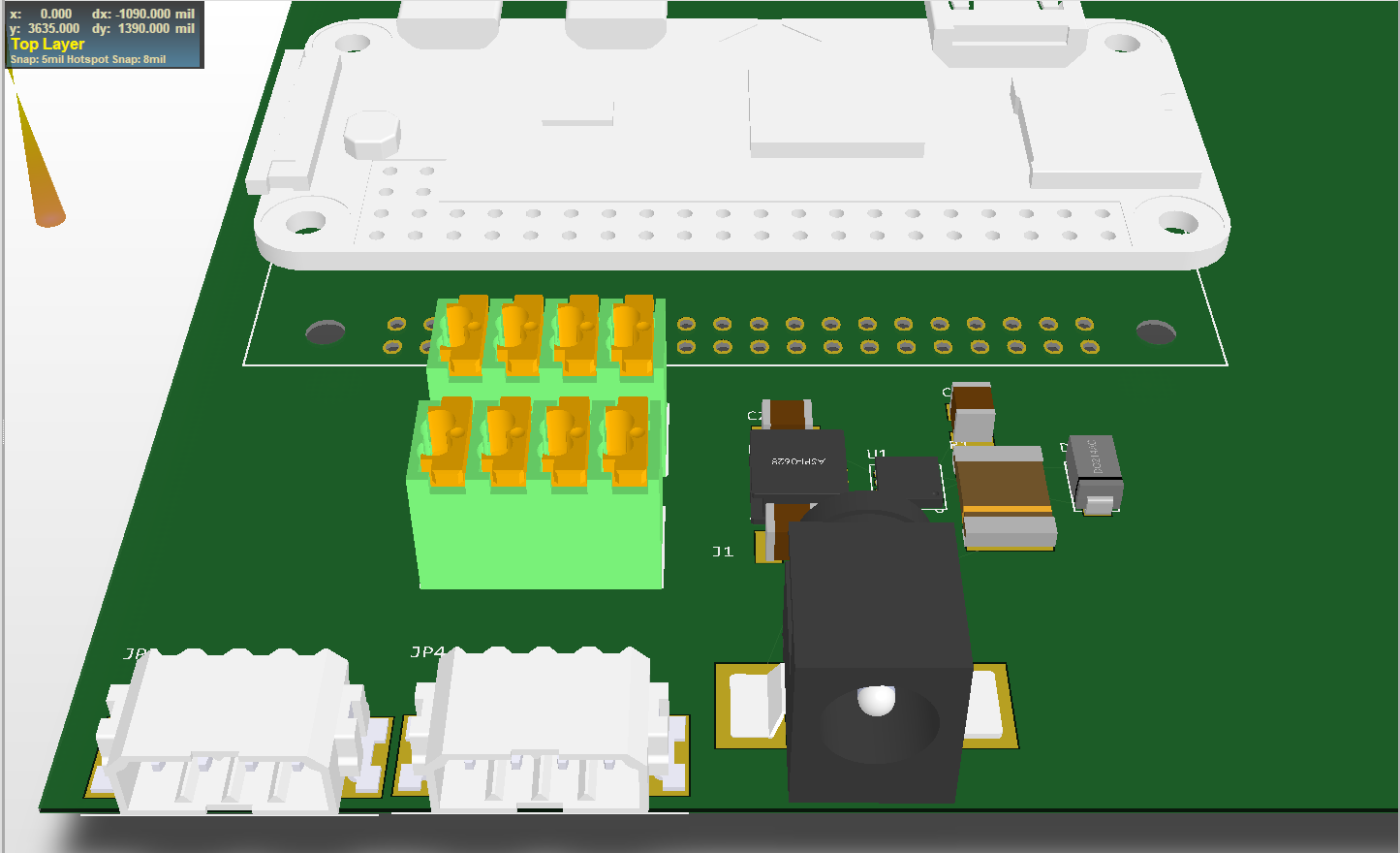

https://www.amazon.com/gp/aw/d/B008UY5WL0 what i bought for the rj45 connections. I actually like the ease of wiring/cost. I hate audio jacks, i always mis wire them lol.

Seconded - audio jack connectors are more of a pain to solder to or crimp to. Would you vote for RJ45 over a more conventional terminal block?