- Joined

- May 23, 2018

- Messages

- 182

- Reaction score

- 421

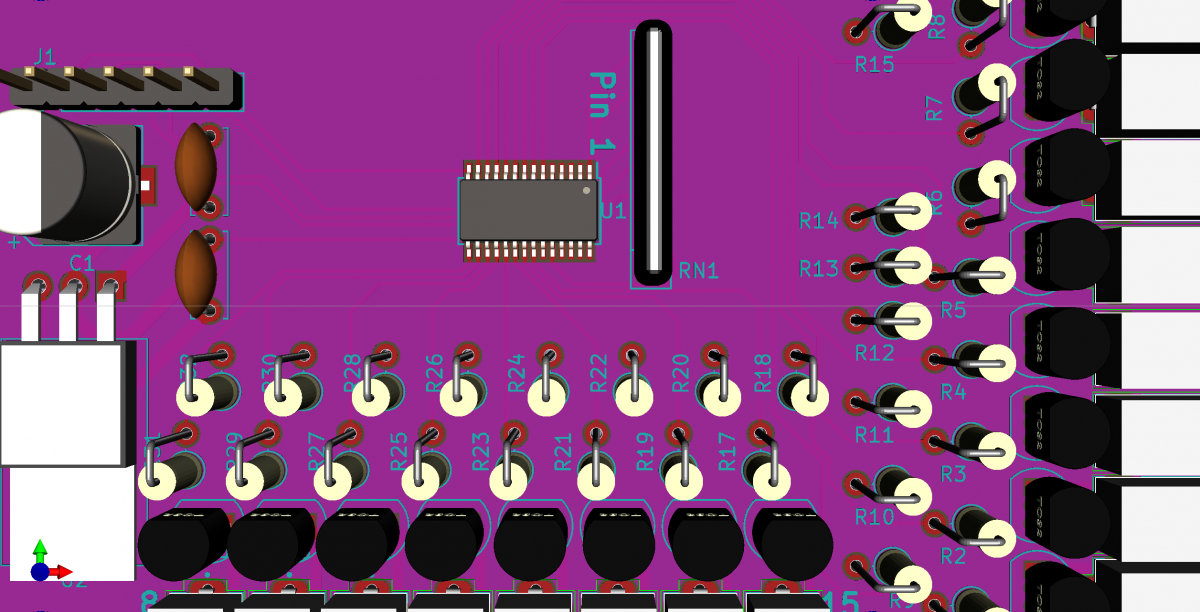

Just uploaded a preliminary document I made for the v0.2 layout but the changes to v1.0 are minimal. On page 6 chapter 3 you can see location of pin 1. It should also be written on the silk screen:

after installation of the PCA9685 I recommend to test for any potential short cuts and if ok run an i2cdetect test. It will give a random i2c address since the resistor array is still missing but you can see if the chip is working. I didn't solder the J1 pins, just inserted it with some pressure from the side with some external wiring to the Reef-PI_HAT and that worked for me.

after installation of the PCA9685 I recommend to test for any potential short cuts and if ok run an i2cdetect test. It will give a random i2c address since the resistor array is still missing but you can see if the chip is working. I didn't solder the J1 pins, just inserted it with some pressure from the side with some external wiring to the Reef-PI_HAT and that worked for me.

Last edited: