- Joined

- May 2, 2011

- Messages

- 71

- Reaction score

- 64

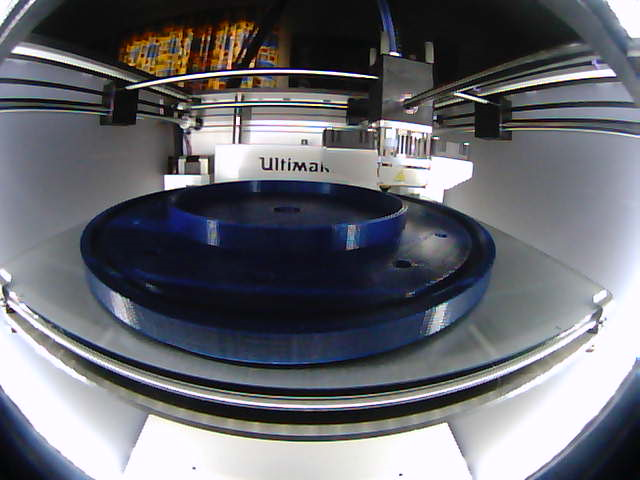

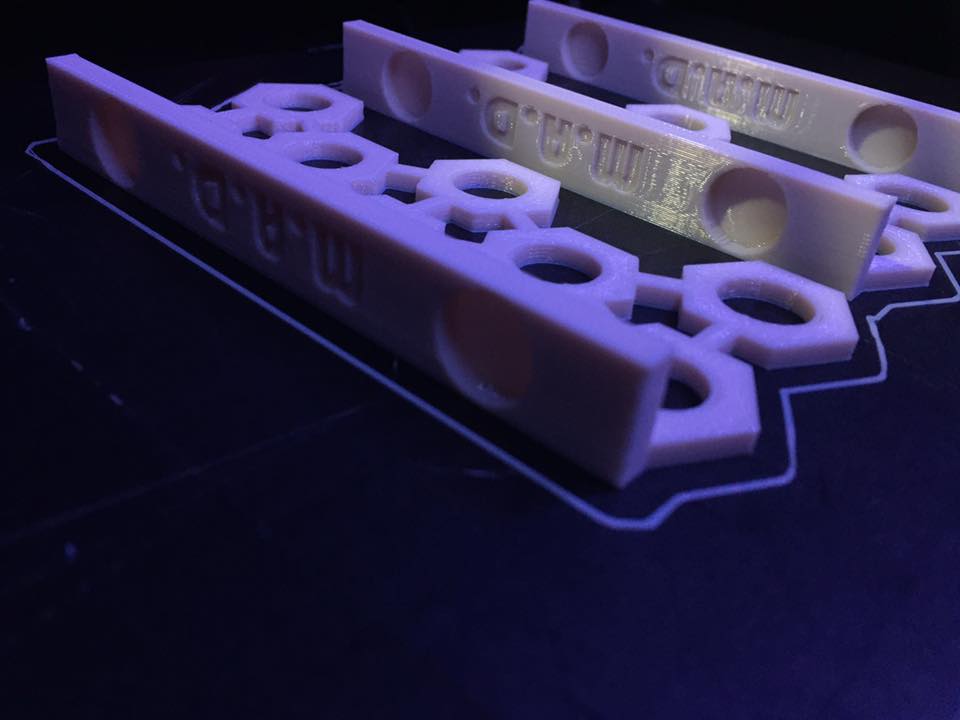

Many of us reefers are now into the hobby of 3D printing as well. Awesome little tool that can bring our what if's to life! I have been tinkering around with Frag racks and I would like to share them with the reefing community.

So here is to the start of what can be a great big repository of 3D printed goodies!

All my files will be shared via Thingiverse and will continue to update them with time. Of course I ask any and all my designs to be used solely for your personal use and not for re sale. I simply want to give back to the community that has helped me in the past learn everything i know today.

https://www.thingiverse.com/illconn/designs

So here is to the start of what can be a great big repository of 3D printed goodies!

All my files will be shared via Thingiverse and will continue to update them with time. Of course I ask any and all my designs to be used solely for your personal use and not for re sale. I simply want to give back to the community that has helped me in the past learn everything i know today.

https://www.thingiverse.com/illconn/designs