- Joined

- Apr 20, 2018

- Messages

- 276

- Reaction score

- 284

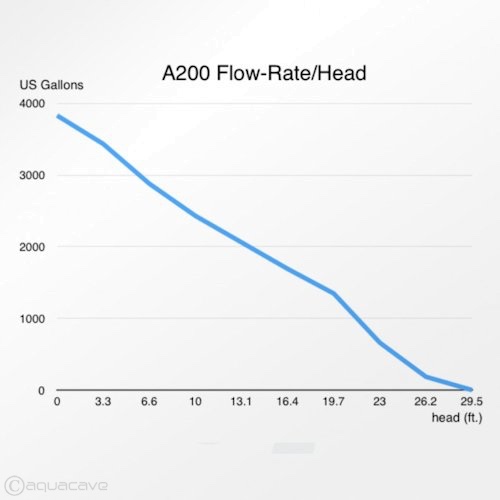

So are these Vecta pumps extremely over rated or do the flow meters restrict flow by a fair amount?

I just setup my new Vectra S1 with a 1in flow meter on a reefer525 and apex is reporting a max GPH of 252... This flow report on a 140gal tank is causing me concern. I've adjusted the FMM to 1in in the settings etc. The actual tank return is 3/4in thus my 1in flow meter is adapted down to 3/4in also and I'm wondering if this also is of issue?

Thanks for any help!

I just setup my new Vectra S1 with a 1in flow meter on a reefer525 and apex is reporting a max GPH of 252... This flow report on a 140gal tank is causing me concern. I've adjusted the FMM to 1in in the settings etc. The actual tank return is 3/4in thus my 1in flow meter is adapted down to 3/4in also and I'm wondering if this also is of issue?

Thanks for any help!