- Joined

- Jul 23, 2014

- Messages

- 402

- Reaction score

- 424

Well dont go shopping before your tenant has a chance to give you the real numbers

hahaha! I already found one! But man...$$$. Rimless and low lead front and side panels...

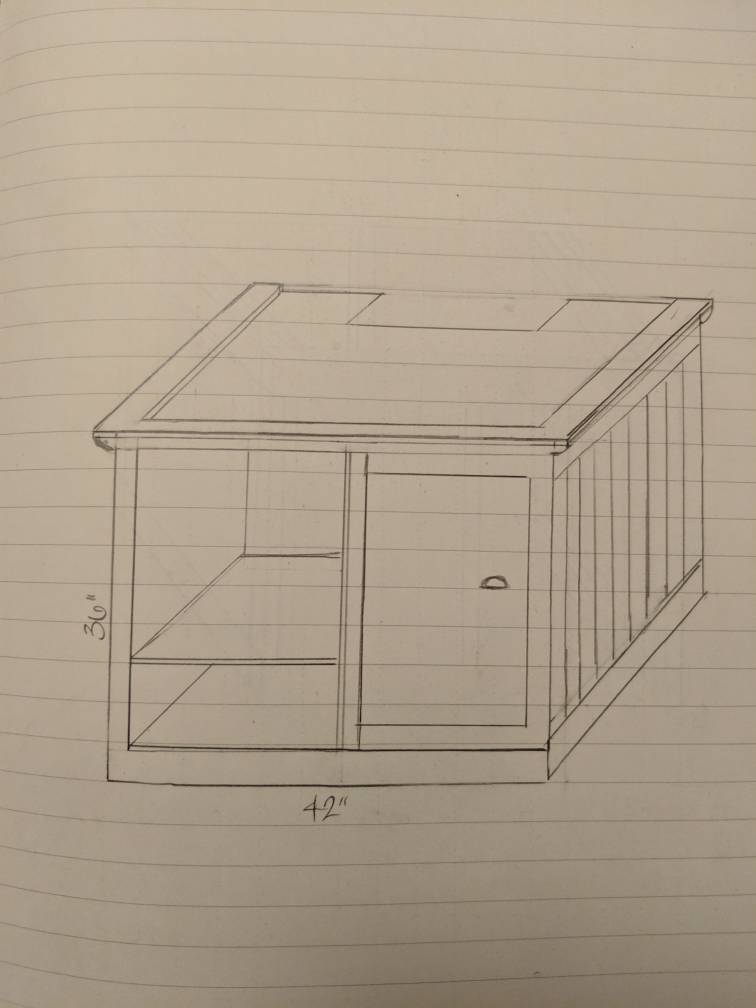

Another option is to block that area and simply cut an access point in the wall under the stairs. I just need to be able to service the Robot and the empty the receptacle. I can make a mock stand and see how it all fits. Then open up a small "window" to allow me to do what I need. I also have an upstairs closet I could move the litter box to possibly.... I'm not sure I'm ready to drop $1K on a new tank when I'm planning on buying a lot of new fancy gadget equipment.