I am setting up a 180 gallon and doing pvc plumbing for the first time. Got everything glued together, put water in the tank, and found one small leak in a section of the return where presumably I didn't use enough glue on the fittings. It would be very difficult to cut out and fix, and I'd probably have to re-do the entire return section which has two returns, a manifold, and a uv sterilizer. The leak is in a very small section where there is about an inch of pvc pipe between two fittings. Can I use silicone/sealant and seal the whole section? Will that hold very long? Or alternatively, could I put some solvent on the pipe and the outside of the fitting and weld them together a little more?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leak in PVC plumbing

- Thread starter knd342

- Start date

- Tagged users None

#WelcometoR2R!!! I understand your dilemma - I've been there. If you have the ability to cut out a section and reinstall with PVC union fittings then that is what I recommend.

Very lame video BUT it might be worth a shot. Otherwise you will need to take the plumbing apart as mentioned above

Oh and some pictures of where the leak is might also be helpful, maybe we could come up with a plan to make replacing it a little easier

BTW congratulations on only one leak!! Some are not as fortunate as you in that

Last edited:

This. I was in your same position when i hard plumbed my tank. I tried everything....PVC patch tape, gluing over the area, even flex glue....guess what..i cut it out and reinstalled. It sucks put seriously do it before it becomes and issue later.#WelcometoR2R!!! I understand your dilemma - I've been there. If you have the ability to cut out a section and reinstall with PVC union fittings then that is what I recommend.

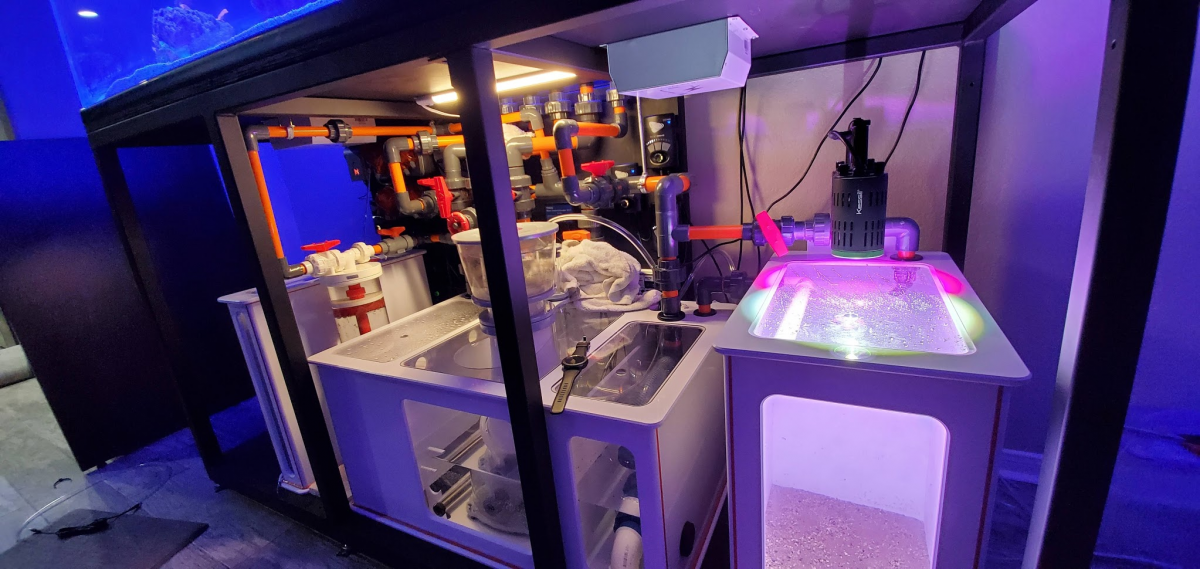

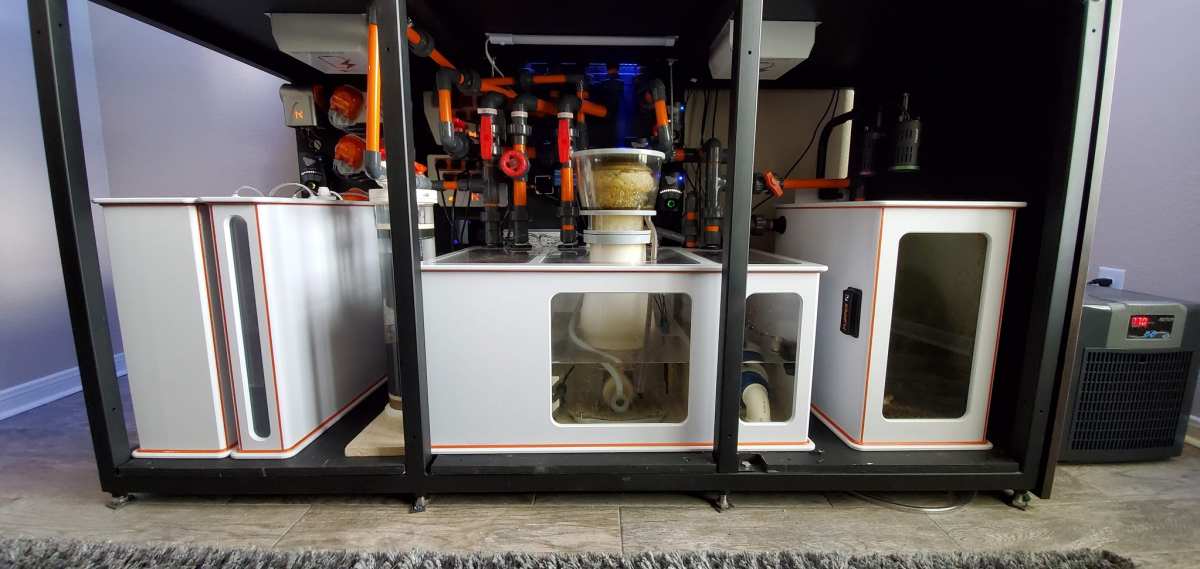

Here are pix for context:

The towel wasn't a decoration.....

All done

Last edited:

If you have a way to hook a shop vac up to the pipe you can create suction on the pipe and try adding glue to the leaking area. What you're trying to do is get the vacuum to suck the glue into where the leak is. Worth a shot... I've done this in the past and it worked. Plus the end of the pipe, hook up the vacuum and apply glue where the leak is. Once it sucks the glue in, turn off the vaccum.

Could use some advice on replacing -- I think my main problem here is that the length of the pipe where the leak is is so short, I don't think I can cut out the leaking fitting and have enough pipe left over to glue another one to. I've learned a lot going through this design/build process -- for instance next time I'll use longer sections of pipe -- but as to how to replace this particular fitting, any recommendations?This. I was in your same position when i hard plumbed my tank. I tried everything....PVC patch tape, gluing over the area, even flex glue....guess what..i cut it out and reinstalled. It sucks put seriously do it before it becomes and issue later.

Here are pix for context:

The towel wasn't a decoration.....

All done

Thats a tough one. You will prolly need to rebuild the entire manifold. Pix would be helpful.Could use some advice on replacing -- I think my main problem here is that the length of the pipe where the leak is is so short, I don't think I can cut out the leaking fitting and have enough pipe left over to glue another one to. I've learned a lot going through this design/build process -- for instance next time I'll use longer sections of pipe -- but as to how to replace this particular fitting, any recommendations?

This is what I've done in the past and it's worked without fail.

Post in thread 'Rob's Really Rad 180 Reef Rally' https://www.reef2reef.com/threads/robs-really-rad-180-reef-rally.722791/post-7990912

Post in thread 'Rob's Really Rad 180 Reef Rally' https://www.reef2reef.com/threads/robs-really-rad-180-reef-rally.722791/post-7990912

hi ,if you can stop the leak,not pretty but works,no primer ,1 good coat ,let dry 4hrs ,feel for water,none recoat 2hrs turn back on.your pipe is in a good position to let glue wrap around

If you have a way to hook a shop vac up to the pipe you can create suction on the pipe and try adding glue to the leaking area. What you're trying to do is get the vacuum to suck the glue into where the leak is. Worth a shot... I've done this in the past and it worked. Plus the end of the pipe, hook up the vacuum and apply glue where the leak is. Once it sucks the glue in, turn off the vaccum.

I have done this to several sections that leaked that did not have a lot of pipe between the fittings. Dry with a hair dyer. Clean with primer. Apply glue around the entire pipe and turn on the vacuum. If you can't/don't want to redo that section, give it a try.

Dry the area and slather on some solvent and then let that dry. That your leak is on the return complicates things somewhat due to higher pressure, but it will probably work. The other option would be to take a spare fitting, cut off a piece that will fit between those two installed fittings, remove about a 1/4 of it so that you can snap it over the pipe. Once you have it dry fitted, put a bunch of solvent on the pipe, re-snap it on, rotate it back and forth a few times (with the cutout section pointed up). I've done this before and it always works.

congrats on new build!! when it comes to something that we invest so much in , its not worth taking the chance sealing it from the outside. im a pipe welder by trade , and ill tell you its always the tinyiest little hole that can wreak havoc when its not found in time. i would cut the pipe , glue a union on each side and tighten the unions bac. helpful for working on it in in the future aswell. make sure you prime and clean fittings prior to gluingI am setting up a 180 gallon and doing pvc plumbing for the first time. Got everything glued together, put water in the tank, and found one small leak in a section of the return where presumably I didn't use enough glue on the fittings. It would be very difficult to cut out and fix, and I'd probably have to re-do the entire return section which has two returns, a manifold, and a uv sterilizer. The leak is in a very small section where there is about an inch of pvc pipe between two fittings. Can I use silicone/sealant and seal the whole section? Will that hold very long? Or alternatively, could I put some solvent on the pipe and the outside of the fitting and weld them together a little more?

Really appreciate all the insight and replies! This has given me a lot of options and a lot to consider.

I was really tempted try a patch job, but ultimately I think that this is the time to do a full fix since there is nothing in the tank but water right now, and nothing is rushing me except my eagerness to get this going. I picked up a 'fitting saver' and I'm going to drill out the leaking pipe and replace it. Question - has anyone done this and should I be concerned about the future stability of the saved fitting?

I am also curious about the recommendations to place a union. Granted I'm (clearly) new to the plumbing game, but I don't think there is enough pipe there (picture 1) to glue anything onto, not even a coupler, if I cut it. That means I couldn't just replace the leaking tee, I'd have to replace a pretty large section. Probably most of the return, which goes up from the pump, tees to the two return lines, one of which then breaks off for a UV sterilizer and the other holds a manifold. I just can't see how I'd repair this without the fitting saver, or without replacing everything (picture 2). Definitely interested in details if someone can speak to them on how this would work.

I was really tempted try a patch job, but ultimately I think that this is the time to do a full fix since there is nothing in the tank but water right now, and nothing is rushing me except my eagerness to get this going. I picked up a 'fitting saver' and I'm going to drill out the leaking pipe and replace it. Question - has anyone done this and should I be concerned about the future stability of the saved fitting?

I am also curious about the recommendations to place a union. Granted I'm (clearly) new to the plumbing game, but I don't think there is enough pipe there (picture 1) to glue anything onto, not even a coupler, if I cut it. That means I couldn't just replace the leaking tee, I'd have to replace a pretty large section. Probably most of the return, which goes up from the pump, tees to the two return lines, one of which then breaks off for a UV sterilizer and the other holds a manifold. I just can't see how I'd repair this without the fitting saver, or without replacing everything (picture 2). Definitely interested in details if someone can speak to them on how this would work.

Attachments

I like this idea a lot. Right now I'm thinking I'll try to drill out the pipe, but if that fails, this seems like a good recovery option. This should melt the edges of the fittings all together, right? Regarding the pressure, it's fairly low even for a return. I think my pump is a little undersized -- I have the Jebao DCP-5000. So I also want to plan for increased pressure in the future when I upgrade.Dry the area and slather on some solvent and then let that dry. That your leak is on the return complicates things somewhat due to higher pressure, but it will probably work. The other option would be to take a spare fitting, cut off a piece that will fit between those two installed fittings, remove about a 1/4 of it so that you can snap it over the pipe. Once you have it dry fitted, put a bunch of solvent on the pipe, re-snap it on, rotate it back and forth a few times (with the cutout section pointed up). I've done this before and it always works.

Never bothered with a fitting saver. They're expensive and always seemed like the proverbial 'sledge hammer to crack an egg'. Frankly, a small leak in a low pressure aquarium PVC line just isn't a big deal. Try the solvent slather approach first. I bet it fixes the problem.

At this stage of tank setup, since you are thinking about replacing, I would replace everything from that union on the far right to and including the "Y" on the left. You can buy replacement slip couplers for those valves individually from BRS.

I would just slather some glue on there first, before I cut it all out and replaced it. Worst case scenario is you end up cutting it out and replacing anyways. So why not try the quick fix first?

I had a small drip on my mixing station, slathered on some primer and solvent. It hasn't leaked in 4 years. Depending on how much it drips, salt creep may seal it up eventually too.

I had a small drip on my mixing station, slathered on some primer and solvent. It hasn't leaked in 4 years. Depending on how much it drips, salt creep may seal it up eventually too.

To update: I ended up going out and getting a fitting saver and drilling out the old pipe and replacing it. Let it dry overnight and fired the return up again today. It worked wonderfully, and I feel a lot more confident dealing with leaks --- it wasn't as big a deal as I thought it would be.

Which is a good thing, because now I've discovered another teeny leak further down in that run. I'm going to let the system run for the day to identify any others before I rip it up again tonight and replace that section, sigh.

I'm going to let the system run for the day to identify any others before I rip it up again tonight and replace that section, sigh.

Thank you to everyone for the ideas and advice!

Which is a good thing, because now I've discovered another teeny leak further down in that run.

Thank you to everyone for the ideas and advice!

Similar threads

- Replies

- 3

- Views

- 97

- Replies

- 12

- Views

- 450

- Replies

- 2

- Views

- 105

- Replies

- 5

- Views

- 120