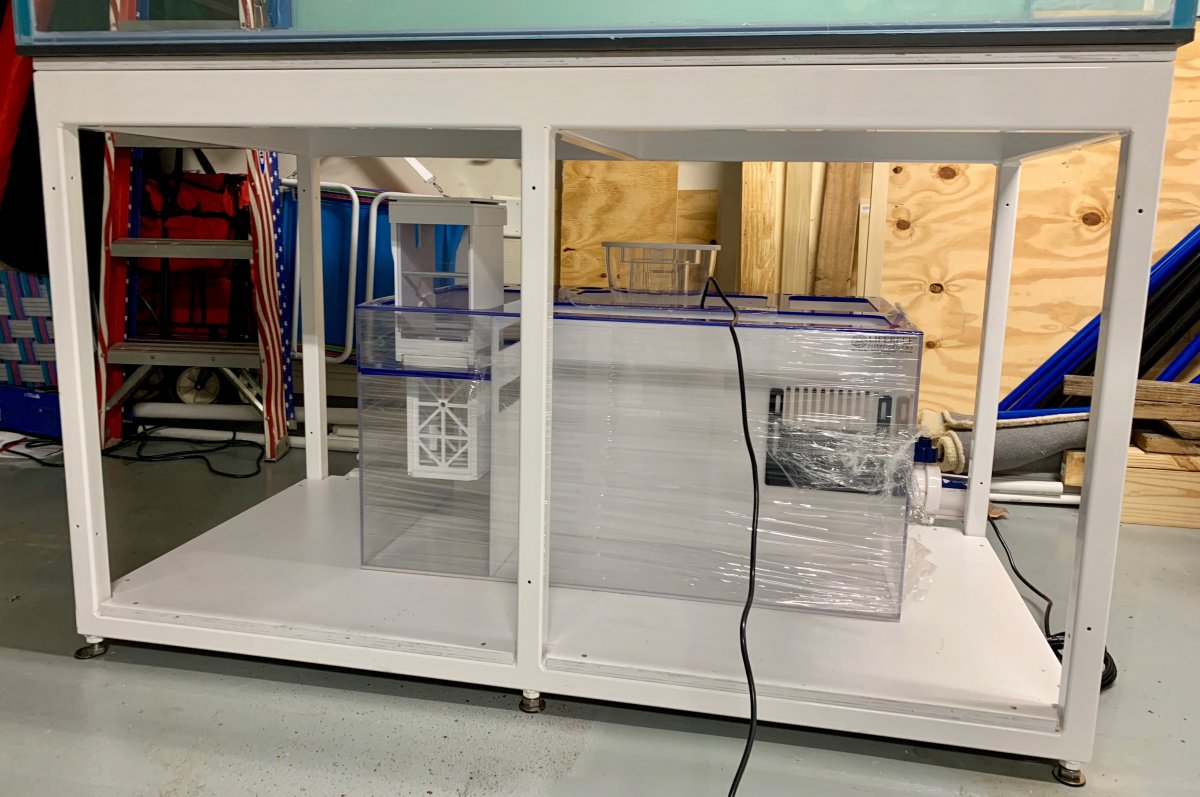

The new stand is in the garage!

Way more room under the tank, and above the sump. Still need to work out the best placement, and where the two giant UV tubes will go. Likely I'll pull the sump forward a bit and put them both vertically behind the tank.

I plan to work on this over the weekend and at least get things planned out, plumbing and wood facing. The sump is about finished with my minor tweaks, so I should be able to clean it out and get all the fixtures attached as well.

Way more room under the tank, and above the sump. Still need to work out the best placement, and where the two giant UV tubes will go. Likely I'll pull the sump forward a bit and put them both vertically behind the tank.

I plan to work on this over the weekend and at least get things planned out, plumbing and wood facing. The sump is about finished with my minor tweaks, so I should be able to clean it out and get all the fixtures attached as well.